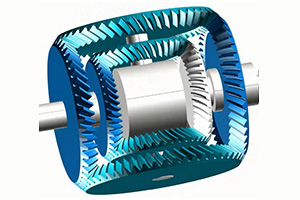

Double Differential for Electric Vehicle and Hybrid Transmissions — Sophisticated Simplicity

The fascination with the automotive differential has led to the idea to build a second differential unit around a first center unit. Both units have the same axes around which they rotate at different speeds. The potential of double differentials as ultrahigh reduction speed reducers is significant. Only the tooth count of the gears in the outer differential unit must be changed in order to achieve ratios between 5 and 80 without a noticeable change in the transmission size.

Webcast Auction of Large Bearing Manufacturer

Late Model 144” Phoenix VTC, 144” Phoenix VTC, 118” & 96” Youji CNC VTC’s, Phoenix Gear Gasher (2007), 100” Fellows Gear Shaper, Ajax Tocco Induction Ring Heaters, 74,000 Lb. Aronson Positioner, Vertical Spindle Grinders, Shop Equipment & More

Read More

e-Mobility & Low Pressure Carburizing with ECM

LPC with HPGQ is optimal for drivetrain heat treatment systems with the industry transition from ICE to EV. Electric vehicle drivetrains demand very low distortion, and automotive manufacturers require very consistent, high-quality results which are achieved when performing low pressure carburizing/high pressure gas quenching in ECM vacuum furnaces.

Read More

Transmission Noise Challenges? Go nano.

Gleason’s new 300GMS nano Gear Metrology System is built for today’s unprecedented transmission noise challenges and tooth form quality requirements. 300GMS nano delivers sub-micron analysis of tooth surface roughness after polish grinding; applies Advanced Waviness Analysis tools to detect and mitigate critical noise behavior caused by hard-to-find tooth form irregularities.

More Information

The perfect E-Shaft

Integrated Complete Processing Raw to Finished Part

The pioneering integrated production solution, of the @DVS TECHNOLOGY GROUP allows highly economical complete machining of Monoblock E-shafts from raw to finished part. DVS Group has bundled the competencies of its subsidiaries @WMZ Werkzeugmaschinen, @Buderus Schleiftechnik and @Präwema Antriebstechnik.

Read More

A New Dimension in Productivity

With Star SU Scudding® and skiving tools, quality meets speed with productivity 5 times faster than conventional gear cutting processes. Achieving surface finish and quality level far superior to traditional gear cutting technology, skiving allows the machining of internal or external gears/splines without the need of an undercut or groove.

Read More

Rego-Fix Celebrates 50th Anniversary of the Original ER Collet

his year marks the 50th anniversary of a revolutionary invention that changed the way today’s manufacturers hold metalworking cutting tools. What has been an industry standard for decades now, the Rego-Fix ER collet is the most widely used clamping system in the world and still produced at the company’s Tenniken, Switzerland, plant.

Read More