Lehigh’s Summer Engineering Institute Students Tour at Solar Atmospheres

Solar Atmospheres hosted over 40 high school students enrolled in the Summer Engineering Institute (SEI) at Lehigh University. Under the guidance of Director Dr. Laura Moyer, the SEI program is a two-week residential program, running two back-to-back sessions. The students experienced a manufacturing setting encompassing related topics from their curriculum, gaining a better understanding of heat treating and manufacturing, and how cutting-edge technology reshapes centuries-old processes.

Third Integrated Robotics Vacuum Furnace System by ECM for Increasing Heat Treat Automation Demands

ECM USA has partnered with the prominent global manufacturer, SEW-EURODRIVE, to commission a modular NANO vacuum furnace system completely integrated with advanced automation for their Lyman, South Carolina facility. It is the third ECM NANO system with integrated robotics and advanced capabilities for the US heat treat market within the last two years. This 6-chamber, 20-bar quench NANO vacuum furnace system provides maximum flexibility and integration utilizing the addition of 16 tempering positions, advanced solvent-based washer (both oil and water-based contaminants), and robotic workload assembly/disassembly.

Insights on Atmospheres for Heat Treating Equipment

Surface Combustion is a leader in controlled atmosphere heat treating furnaces and atmosphere generators. Learn detailed information about heat treat atmospheres including, descriptions, compositions, generation methods, and applications. This is a fantastic resource for heat treat operators, metallurgists, and maintenance technicians. Contact Surface Combustion to discuss your specific requirement.

ECM Heat Treat Robotics & Advanced Automation

BREAKING THE BARRIER BETWEEN FURNACE SYSTEM AUTOMATION AND ADVANCED HEAT TREAT ROBOTICS! Upgrade your operation with ECM Robotics specific to heat treating for consistent production flow and controlled labor expenses. Integrate your system (including washers, tempers, cryos…) with leading-edge automation technology for efficient part sorting, workload assembly/disassembly & AGV transport.

Read More

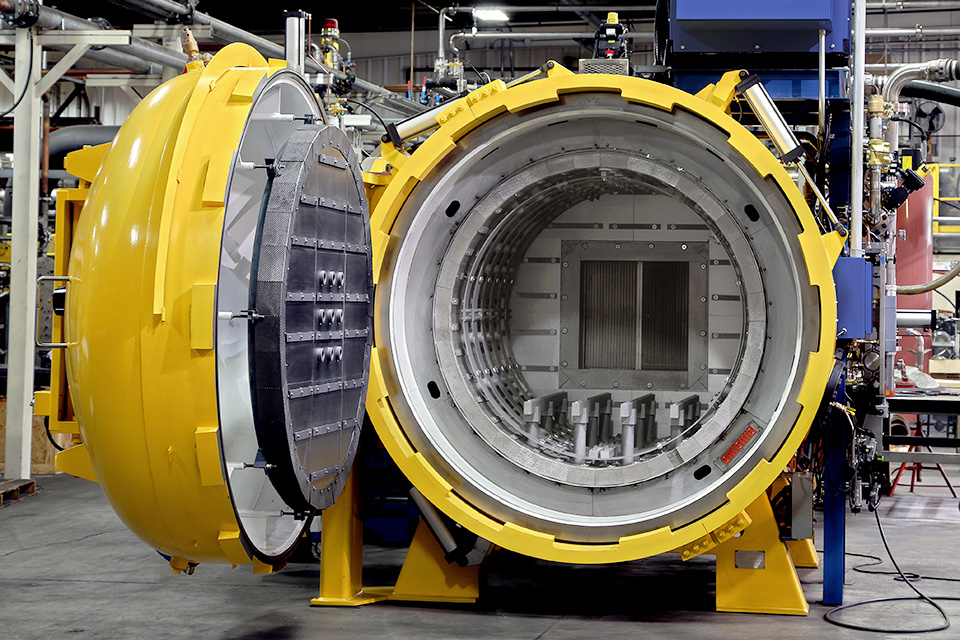

High Pressure Quench Vacuum Carburizing Furnaces

Get fast, forceful gas cooling with Solar Manufacturing’s IQ series of vacuum carburizing furnaces. It’s high performance internal quench system with direct-exit, sliding radiation baffles is the least restricted gas flow path on the market for superior hardening at quench pressures up to 20 bar.

Contact us to learn more about our vacuum furnace ingenuity.

P: 267.384.5040

Read More

Solar Atmospheres Now Offers Oil Quenching Capabilities

Solar Atmospheres provides low pressure carburizing (LPC) in vacuum to increase the surface hardness/strength of gearing for improved friction and wear. LPC delivers clean parts with less distortion reducing post process finishing operations, and costs. For lower hardenability alloys and/or to attain higher core hardness on gears, Solar now offers vacuum oil quenching!

Read More

Zero Carbon Target?

Induction is an eco-friendly heating method, as it does not generate carbon during the heating process. The electrification of the automobile and the manufacturing goal of a zero-carbon target process makes induction the perfect solution for heat treating, tempering, brazing, forging, and shrink fitting.

Read More

We've changed the heat treatment color to green

SECO/VACUUM provides green solutions that reduce production energy consumption, increase production efficiency, shorten process and treatment time, and reduce the consumption of energy and process gases.

We’ve changed the heat treatment color to green by offering customers our solutions to make many pro-environmental changes in their industries.

Click to learn more.

Built-for-Stock—Fast Delivery of UBQ Batch Furnace

AFC-Holcroft's innovative Built for Stock program offers us the ability to deliver equipment weeks or months earlier than typical build-to-order delivery. Best of all, there is no extra cost for this accelerated delivery. This program features popular equipment such as batch furnaces, EZ endothermic gas generators, and support equipment.

Read More