Chris Constable Joins the Solar Atmospheres of San Diego Team

Solar Atmospheres’ newest acquisition, Solar Atmospheres of San Diego, is pleased to announce the addition of Chris Constable as their new Vice President of Operations. Chris brings with him nearly 25 years of Heat Treating experience that includes quality, operations, management, plant safety, business development, and sales. Chris is well suited to understanding the customers’ needs and providing effective solutions to their most difficult challenges. Coupled with the Solar Atmospheres knowledgeable and dedicated team, Solar Atmospheres of San Diego stands ready to provide high-quality heat-treating services with a focus on honesty and integrity and a reliable customer service experience.

SECO/WARWICK Group To Expand Their Meadville Manufacturing Facilities

As part of its strategy to better serve its North American customers, the SECO/WARWICK Group, the parent company of SECO/VACUUM and SECO/WARWICK USA, has committed to expanding its manufacturing capacity in Pennsylvania by relocating a portion of its manufacturing and a metallurgical lab for vacuum furnaces from its headquarters site in Poland to Crawford County.

Insights on Atmospheres for Heat Treating Equipment

Surface Combustion is a leader in controlled atmosphere heat treating furnaces and atmosphere generators. Learn detailed information about heat treat atmospheres including, descriptions, compositions, generation methods, and applications. This is a fantastic resource for heat treat operators, metallurgists, and maintenance technicians. Contact Surface Combustion to discuss your specific requirement.

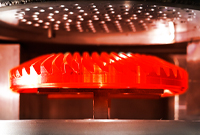

Solar Atmospheres Now Offers Oil Quenching Capabilities

Solar Atmospheres provides low pressure carburizing (LPC) in vacuum to increase the surface hardness/strength of gearing for improved friction and wear. LPC delivers clean parts with less distortion reducing post process finishing operations, and costs. For lower hardenability alloys and/or to attain higher core hardness on gears, Solar now offers vacuum oil quenching!

Read More

Vacuum Furnace Technology with ECM

If you do CARBURIZING, BRAZING, FNC, HARDENING, SINTERING, ANNEALING…then you need an ECM vacuum furnace system to transform the way you heat treat. Our innovative vacuum technology allows for higher temperature treatments to maximize production efficiency, reduce production costs, assure repeatable quality, optimize energy consumption & improve employee safety.

Read More

4D Quench Predicts & Controls Distortion

SECO/VACUUM's UniCase Master® single-piece flow vacuum furnace virtually eliminates all post-heat treatment costs associated with distortion. It takes parts from your machining center, heat treats them under vacuum, quenches from all sides using multiple high pressure gas jets as the part rotates (the 4th dimension), then automatically delivers them to the next manufacturing process.

Learn More

Beat fear of the unknown.

Don’t let fear of tomorrow cripple you today. Here are the 5 methods helping manufacturers achieve greatness today and for the future. Read the 5 Changes Manufacturers are Making Today and for Tomorrow whitepaper now.

Give Me the Whitepaper

Mahr MWF GmbH Develops Measuring Machine for Double-Flank Gear Roll Testing

Mahr MWF GmbH has developed and built a measuring machine for double-flank gear roll testing to meet the individual requirements of a customer. This machine tests the form feature concentricity deviation Fr on the internal toothing of gears.

Read More

Join us for Lubrication & Wear: Advanced Concepts

ABMA is hosting Lubrication & Wear: Advanced Concepts on October 1-3, 2024 at the University of Notre Dame! For more information such as dates and times and registration deadline, click on the link below.

Register Now