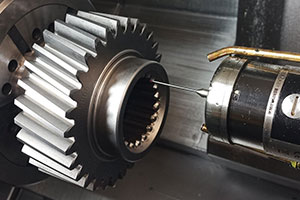

Hard Skiving of an Internal DIN5480 Spline—A Process Analysis

This report uses an application case to demonstrate the optimization potential of gear skiving in the production of internal splines on a universal machining center. The process established in the example is then analyzed using the software tool OpenSkiving developed by the wbk Institute of Production Science of the Karlsruhe Institute of Technology (KIT) and the results are discussed. Finally, the most important findings are summarized.

Customize Gear Skiving for Precise, Efficient Gear Cutting

Manufacturers have a relatively new production option that offers several key advantages—gear skiving on machining centers. Gear skiving on a mill-turn machining center with fully synchronous spindles is highly efficient, fast, and accurate. In some cases when producing small and medium-sized volumes, gear skiving will gradually replace established gear-cutting processes.

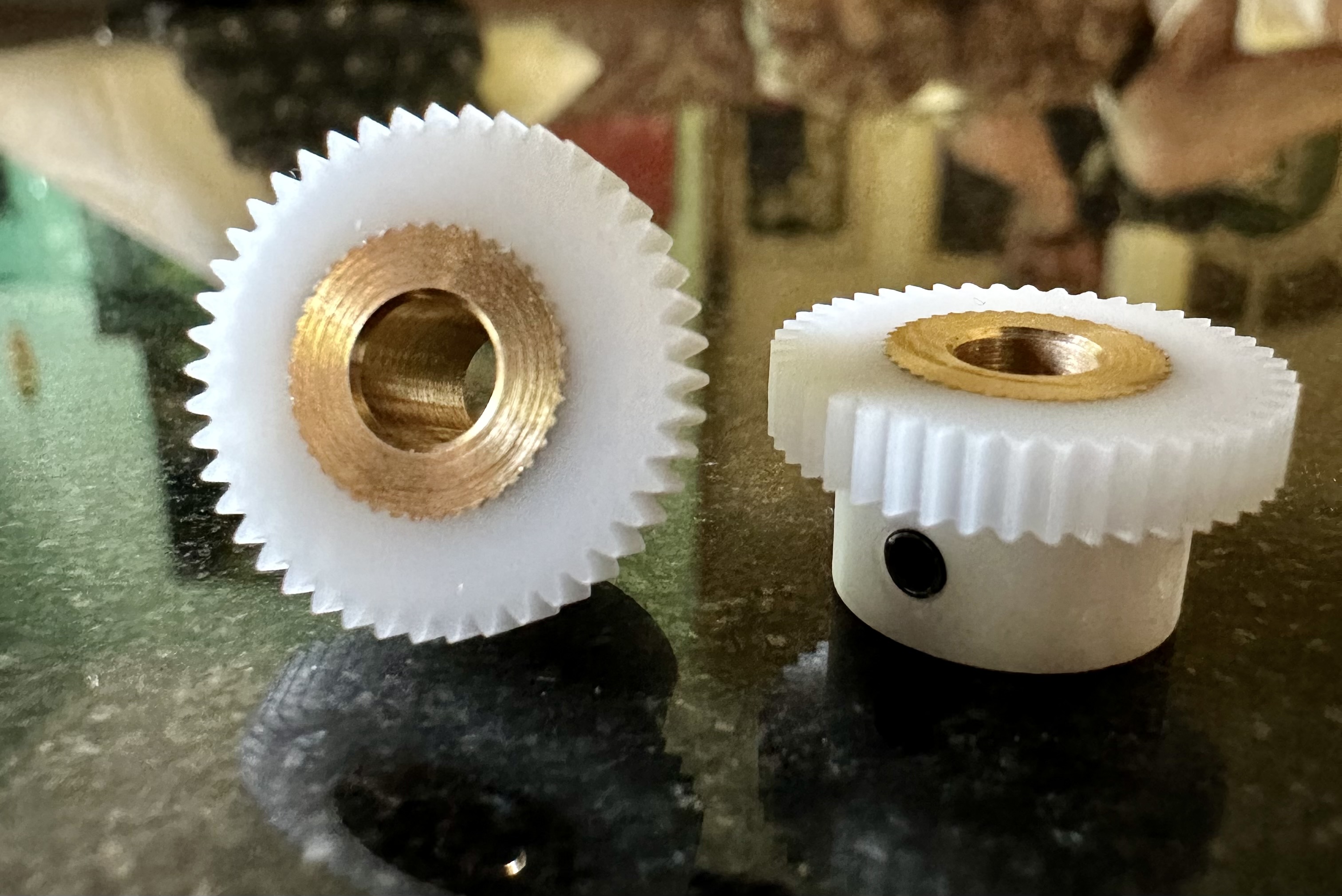

Plastic Gears

The Gear Edges is well established manufacturer of International standard and custom design gears. Wide range of various configurations, teeth number and custom sizes are available in Plastic, Steel, Aluminium and Brass. We give full and part assembly to customers.

We also manufacture Rack and Pinion, Sheet metal Pulley, Poly V pulley, Timing Pulley, Sprockets, Bar stock and bushes.

Read More

GMTA – Systems solution provider for the gear industry

New Profilator S300 machine

- Flexible modular machine platform (skiving, hobbing, pointing, cycloidal milling, chamfering and deburring)

- Single or Twin spindle platforms available

- Optional tool changer turret for maximum machining flexibility

- Siemens One with conversational part programming

- Easy setup and access due to open walk-in work area

Read More

White Paper: Optimize Gearbox Design with the FVA-Workbench Software

FVA GmbH’s latest white paper reveals how the FVA-Workbench software streamlines the gearbox design process. Using a fan gearbox as an example, the paper illustrates how the FVA-Workbench helps you achieve an optimal ratio distribution, develop preliminary geometry, and assess various gearing options swiftly. In just six straightforward steps, you can evolve your initial concept into the ideal product.

Read the full white paper.

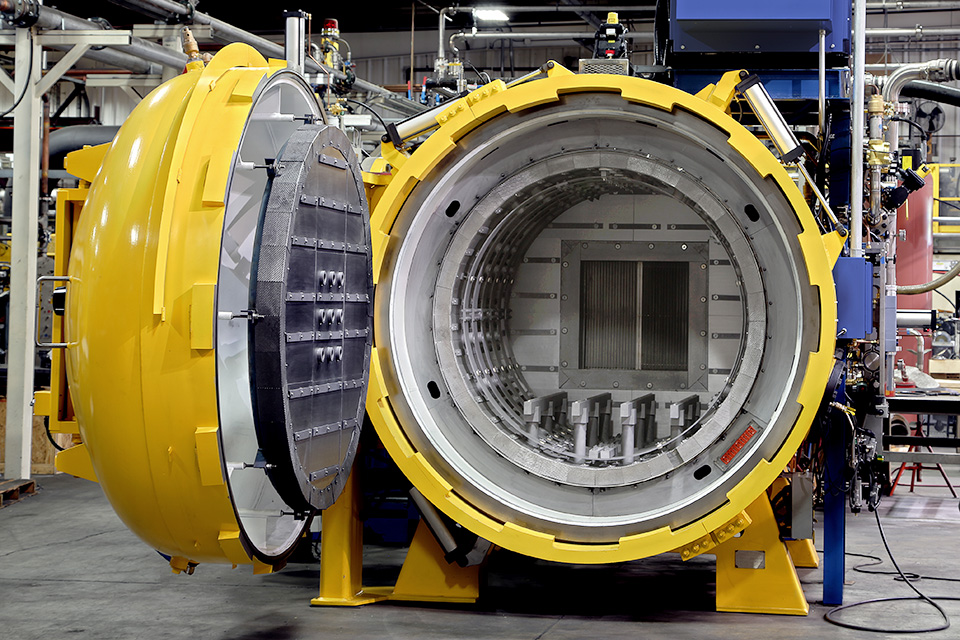

High Pressure Quench Vacuum Carburizing Furnaces

Get fast, forceful gas cooling with Solar Manufacturing’s IQ series of vacuum carburizing furnaces. It’s high performance internal quench system with direct-exit, sliding radiation baffles is the least restricted gas flow path on the market for superior hardening at quench pressures up to 20 bar.

Contact us to learn more about our vacuum furnace ingenuity.

P: 267.384.5040

Read More

Motion to Open New Repair Shop in Houston

Motion Industries, Inc. is pleased to announce a new Motion Repair & Services location at 20710 Sharmon Road, Houston, Texas, 77038. The new shop, which is entirely dedicated to repair and services, is slated to open in September 2024.

Read More

Join us for Condition Monitoring

AGMA is hosting our Condition Monitoring on October 16-17, 2024 online! For more information such as dates and times and registration deadline, click on the link below.

Register Now