|

Get the freshest updates on gear technology

|

|

|

|

| ECM USA Partners with SEW-Eurodrive for Fully Automated Vacuum Furnace System |

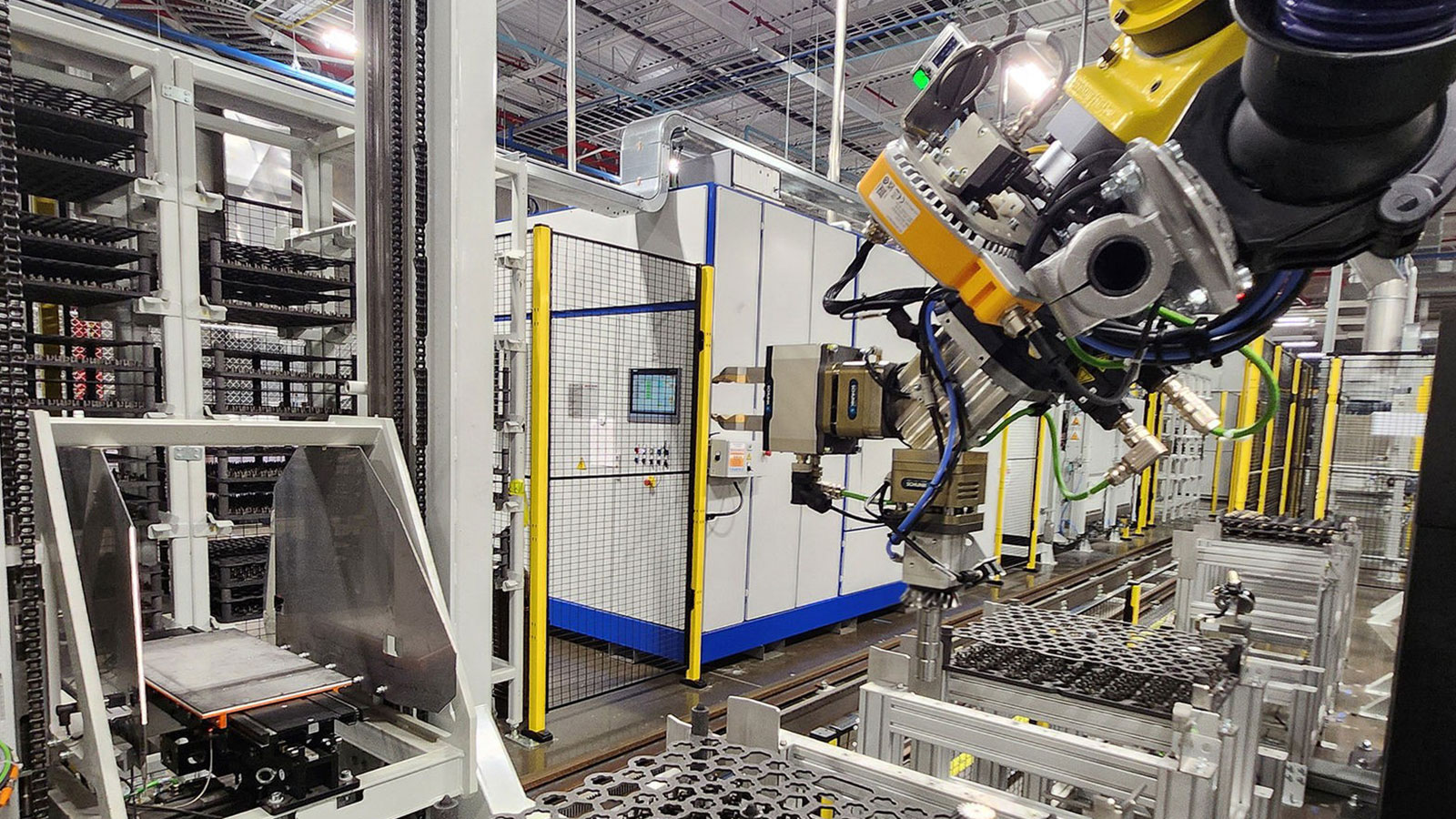

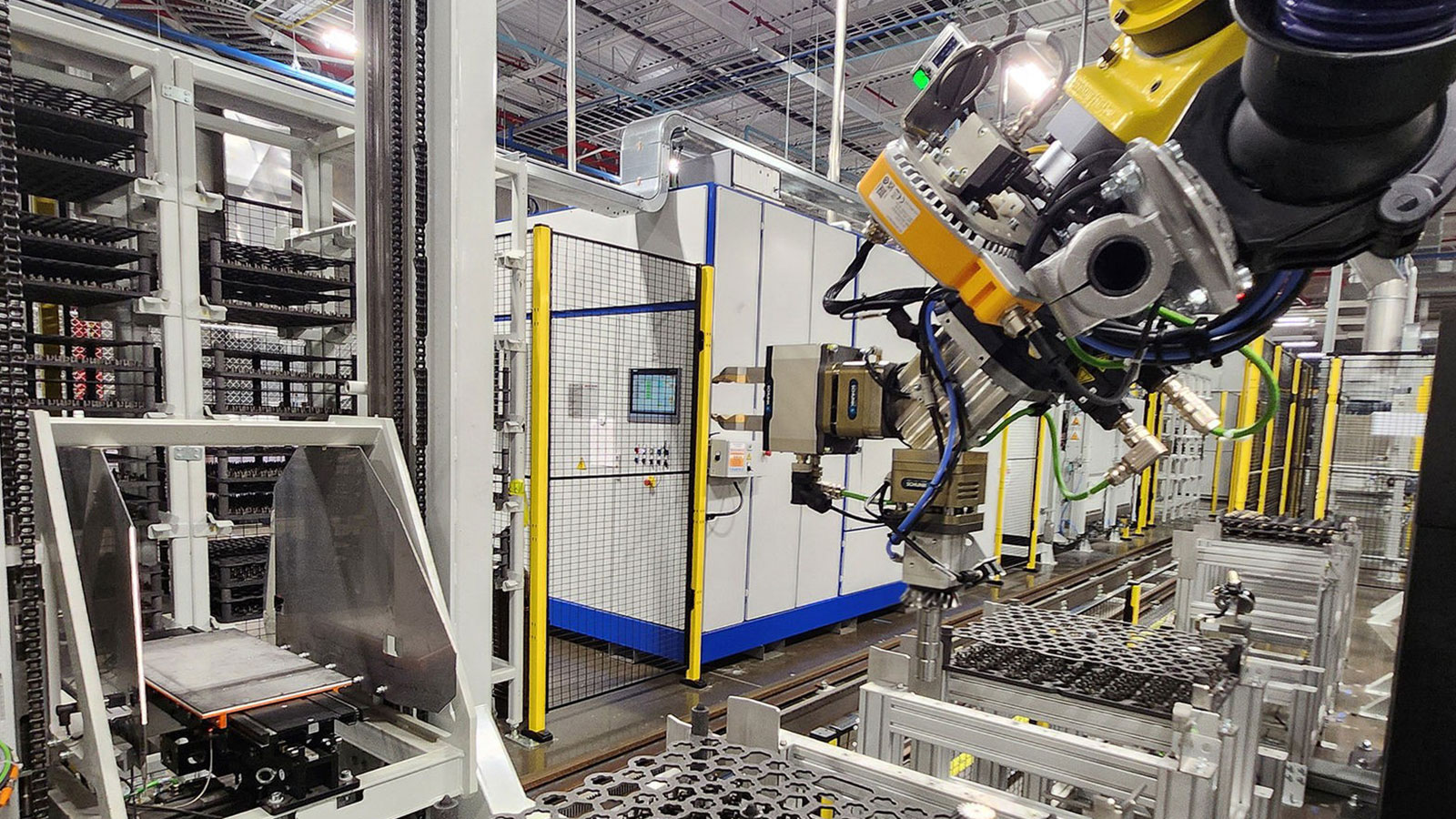

SEW-Eurodrive’s heat treatment team recently completed their fully automated in-house vacuum furnace system integrated with their patented Movi-Trans inductive energy power transfer system (pictured parallel with ECM’s transfer system rails). SEW-Eurodrive partnered with ECM USA to commission a modular Nano vacuum furnace system completely integrated with advanced automation for their Lyman, SC facility in June 2023.

|

|

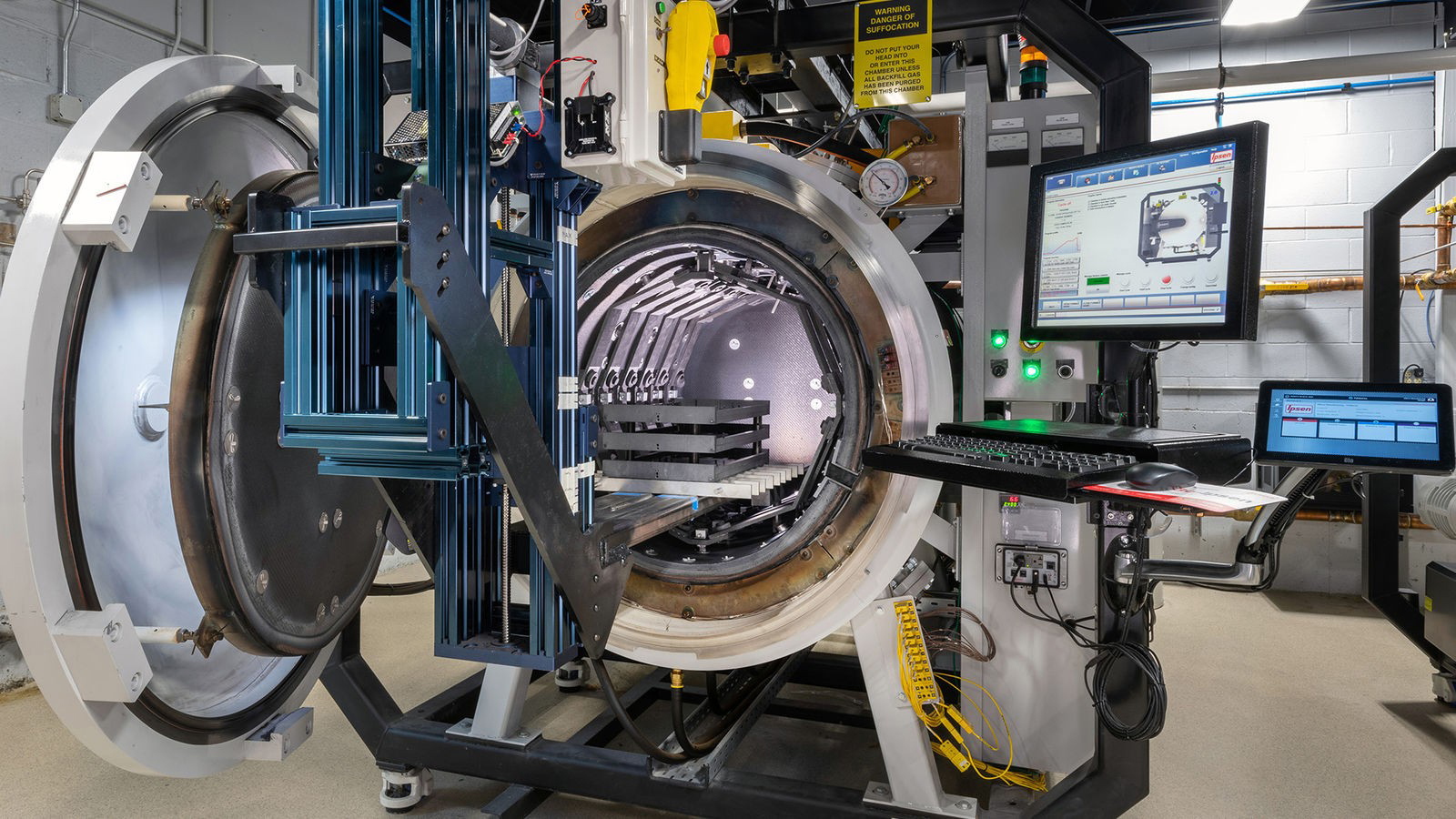

| The Digital Ecosystem with Ipsen |

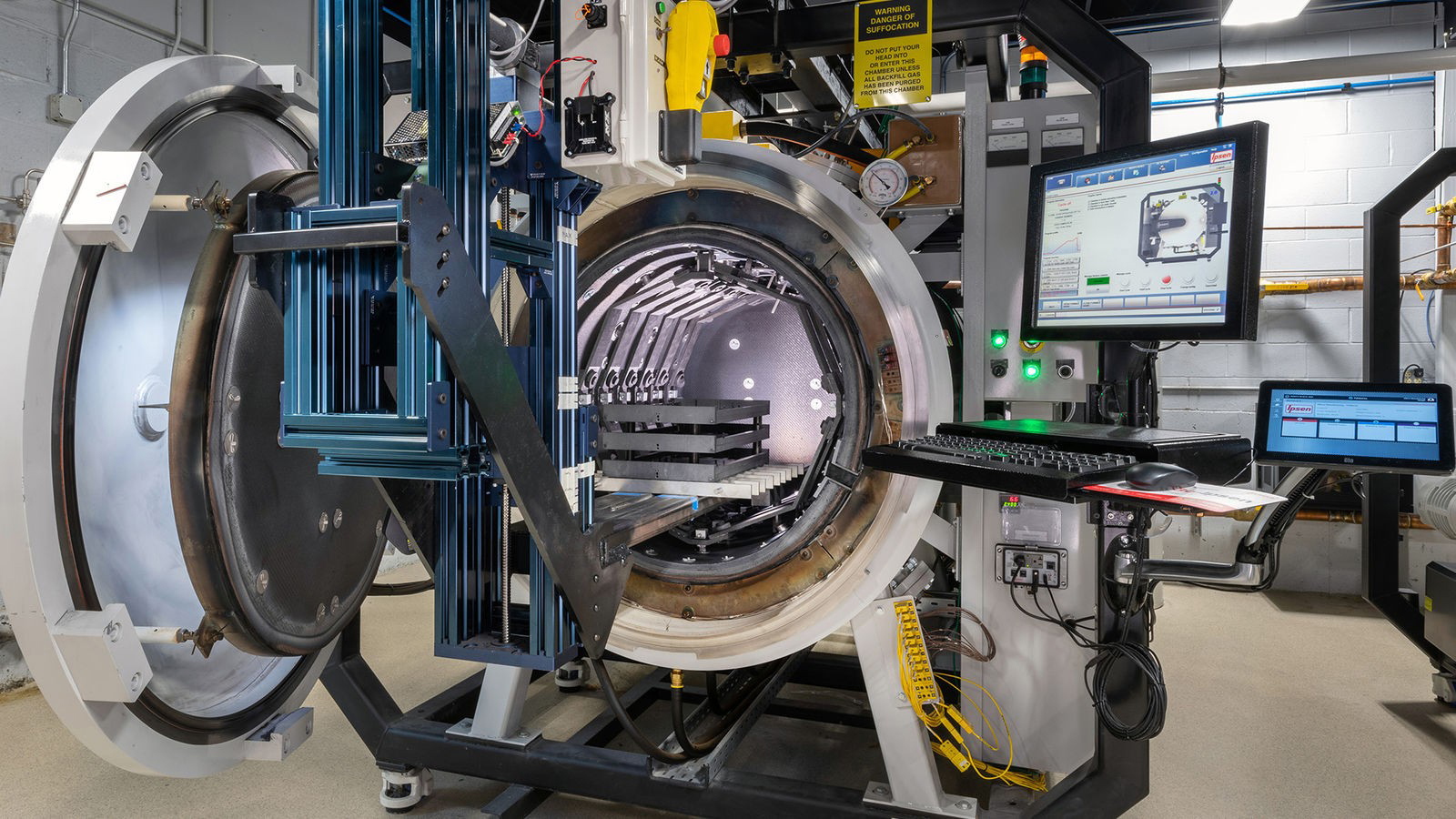

Ipsen is leveraging IIoT, AI, and digital tools like its PdMetrics predictive maintenance system and Ipsen Connect customer portal to reduce downtime, optimize spare parts management, and enhance workforce efficiency in heat treating. By integrating real-time monitoring, automation, and centralized knowledge resources, Ipsen helps manufacturers improve Overall Equipment Effectiveness (OEE) and streamline operations.

|

| [Sponsored Content] |

|

| Cost Considerations and Investment Strategies for In-House Heat Treating |

Setting up an in-house heat treating operation allows businesses throughout many industries to harness this powerful technology and create better-quality metal parts. In this article, Surface Combustion discusses the biggest cost considerations involved in purchasing in-house heat treating technology and investment strategies to ensure you maximize your ROI.

|

|

|

| ThermTech - Press Quenching and Carburizing Gears |

ThermTech delivers unmatched quality and precision in gear heat treatment. Our skilled team, advanced equipment, and dedication to excellence ensure that your gears are treated with the utmost care and technical expertise. Whether you need carburizing, press quenching, or both, ThermTech provides the best heat treatment solutions in the industry.

|

|

|

| Cut Waste. Boost Productivity. |

Pursue a sustainable future with Gasbarre’s multi-chamber vacuum furnaces. Unlike single-chamber designs, multi-chamber systems retain energy, cut emissions, and boost throughput. As low-carbon demand grows, these efficient furnaces are set to replace inefficient models—delivering cost savings, higher productivity, and a reduced environmental footprint.

|

|

|

| World Premiere: LGP 2000 Redefines Profile Grinding |

Discover the new LGP 2000 – our next-gen profile grinding machine for workpieces up to Ø 2,000 mm. Modular, precise, and productive: dual grinding wheels, thermal stability, hydrostatic table, and high-speed grinding ensure top flexibility and accuracy. Set new standards in grinding.

|

|

|

|

| Quality Repeatability with ECM Vacuum Furnace Technology |

CARBURIZING. BRAZING. FNC. HARDENING. If you heat treat, you need an ECM vacuum furnace system. Our innovative vacuum technology allows for higher temperature treatments to maximize efficiency, reduce costs, ensure repeatability, optimize energy consumption & improve worker safety. Watch our new customer testimonial about COMPLETE systems with integrated robotics.

|

|

|

| Custom Engineered Design — When Off-The-Shelf Won’t Cut It |

Every project starts with a challenge and ends with a custom-built system, designed by experts. We deliver heat treatment technologies that power the world’s most demanding industries.

Whether you're looking for standard systems or tailor-made innovations, SECO/WARWICK is where engineering creates results.

We don’t sell furnaces — we engineer solutions.

|

|

|

| Join us for Operator Gear Grinding |

AGMA is hosting our Operator Gear Grinding on September 17-18, 2025 online! For more information such as dates and times and registration deadline, click on the link below.

|

|

|

|