Overcoming Barriers

Depending on who you ask, the Industrial Internet of Things is growing more slowly than anyone predicted. Why is that, and what does that mean for the gear manufacturing industry?

Meeting the Challenge of Gear Noise Analysis

With the surge in Electric Vehicles, gear noise reduction is of paramount importance. Gleason is at the forefront of gear noise analysis, offering a variety of industry-leading metrology tools with its GMS® Analytical Gear Inspection Systems to help minimize noise by optimizing gear design and manufacturing. Download the Gleason Noise Analysis Whitepaper to learn more.

Expand Through Acquisition

Company Highlights

- Sales over $11MM

- EBITDA $4MM (will rise to $5MM by YE 2019)

- 73% Gross Margins

- 32% Net Margins

- No Customer Concentration

- Sales in Upward Trajectory

- Only Working At 30% Capacity

- Low Hanging Fruit for Increased Sales

- Serving Multiple Industries

Read More

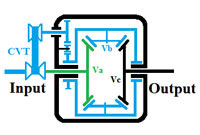

Introducing the NEW GEARBOX GENERATION - Licensing available

The new generation of gearboxes uses a differential.

- No more switching gears

- The motor can be kept running at constant speed, all the time

- Higher efficiency

- Even a small motor can produce a very high starting torque

- The system is reversible (dynamic braking)

- Cheaper to build

Read More

Visit us at the Motion + Power Technology Expo

Live demo of the GearScan 500 in booth 4218!

The GearScan 500 allows for fast detection of common manufacturing problems such as grinding re-tempter burn, heat treatment defects, and other stress related defects. With the GearScan 500, it is easy to control the quality of helical and spur gears with Barkhausen Noise.

Read More

KAPP NILES Metrology - Check more gears!

- Faster with advanced KNM C5 CNC and Windows 10, 64-bit system

- Granite slides, air bearings, active spring damping, thermal comp

- Retracting tailstock and smart tooling for quick, convenient operation

- Smart design without compromise

- KNM 2X, 5X and 9X

Watch the Video

Ask Walter the Secret!

When you visit Motion & Power Technology Expo in Detroit, be sure you stop at booth 4439 and see GMTA, a leader in gear machine technology, as well as laser joining and parts washing equipment for the industry. Say hi to Walter Friedrich and ask him, "OK, Walter, what's the big secret?" He might tell you. If you do broaching, you might want to hear his answer. See you in the Motor City!

Read More

Seco Tools Announces New Duratomic Grades for Stainless Steel Turning

Seco Tools has announced the release of three new grades specifically for stainless steel turning featuring the company’s latest Duratomic generation and its Used-Edge Detection technology. The new TM grades TM1501, TM2501 and TM3501 secure operations and improve productivity in materials ranging from austenitic stainless steel to high-alloyed, super-duplex stainless steels.

Read More