The Numbers Game

Tool-X is a nanofluid that changes the characteristics of existing metalworking fluids by ‘manipulating’ speeds, feeds and metal removal rates using nanotechnology. The science behind Tool-X can potentially change metal cutting dynamics, improve surface finishes and extend tool life. The backstory of this technology is just as fascinating as its production results.

The Benefits of a Coolant Management System

The FlexxCool Coolant Management System offers an efficient way to manage coolant. By automating the coolant process, customers recover labor hours, increase productivity, and improve quality by eliminating human effort and error.

Over 60 years, engineers have relied on Spiroid® gearing.

From robotics to aerospace, our gears provide the most compact, highest torque and customizable solutions on the planet. It’s the perfect balance of torque, efficiency and ratio flexibility.

Find out if Spiroid Gearing is the best fit for your application. Consult our engineers directly today at 320-762-7133.

VISIT OUR CASE STUDY LIBRARY

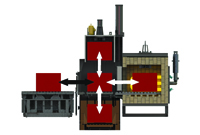

Automation Equipment for Heat Treating Gears

Surface knows the best methods for your gear heat treat processing to ensure the final gear product has the strength characteristics needed for the application. When it comes to effective gear production consider using our batch automation options. Surface engineers will work with you to develop custom OEM automated material handling solutions.

Learn More

NIDEC’s CF26A Chamfer Machine awarded the 53rd IDEA "Judges Committee Special Award" at the 53rd Mac

Come to Motion + Power Expo and see the new NIDEC CF26A cut chamfer machine. NIDEC’s powerful simulation and design software creates the new ChamferX cutting tools for the exact specified chamfer through the entire tooth, including the root. Call Scott Knoy at 248-756-5017.

Read More

See the future of heat treating at ASM Heat Treat Show

If you’re attending the Motion & Power Expo on October 17-19, visit SECO/VACUUM’s booth #2101 at the ASM Heat Treat Show. You’ll see a star-studded line-up of heat treatment technologies, including the innovative 4D Quench® family, designed specifically to improve gear manufacturing well into the future.

Click for a preview and FREE Expo-Only Pass!

Solar Atmospheres Now Offers Oil Quenching Capabilities

Solar Atmospheres provides low pressure carburizing (LPC) in vacuum to increase the surface hardness/strength of gearing for improved friction and wear. LPC delivers clean parts with less distortion reducing post process finishing operations, and costs. For lower hardenability alloys and/or to attain higher core hardness on gears, Solar now offers vacuum oil quenching!

Read More

A New Dimension in Productivity

With Star SU Scudding® and skiving tools, quality meets speed with productivity 5 times faster than conventional gear cutting processes. Achieving surface finish and quality level far superior to traditional gear cutting technology, skiving allows the machining of internal or external gears/splines without the need of an undercut or groove.

Read More