Blaser Examines Every Chip in Detail in an Innovative Series of Tests

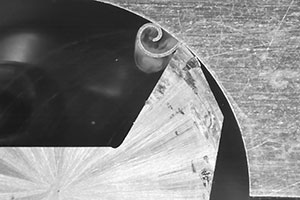

The macro high-speed recordings are impressive: Viewed in slow motion, a carbide milling tool removes a perfectly shaped brass chip. The Blaser Synergy 735 metalworking fluid becomes cloudy around the curling chip—exactly where the heat is greatest. It leaves an oil-like phase and thus forms an even more effective lubricating emulsion. In an extensive series of tests in the in-house Technology Center, the metalworking fluid experts from Blaser Swisslube analyze machining processes down to the finest detail. The principle: To achieve better metalworking fluids faster through expertise and data.

The Numbers Game

Tool-X is a nanofluid that changes the characteristics of existing metalworking fluids by ‘manipulating’ speeds, feeds and metal removal rates using nanotechnology. The science behind Tool-X can potentially change metal cutting dynamics, improve surface finishes and extend tool life. The backstory of this technology is just as fascinating as its production results.

The Future of Sealing: Insights for Gearbox Manufacturers

Join Freudenberg’s webinar to explore sealing innovations tailored for gearbox efficiency. Learn how our seals combine tradition with cutting-edge technology, setting new industry benchmarks.

Master gearbox design: Test the FVA-Workbench for free!

Experience the FVA-Workbench software and discover practical, research-based solutions for your drive technology applications. With advanced tools for load capacity, power flow, system deformation, efficiency, and more, the FVA-Workbench simplifies the simulation and calculation of complete systems and gear components—such as spur gears, bevel gears, bearings, shafts, and shaft-hub connections—making it easier and more reliable than ever.

Start Your Free Trial

oelheld’s DiaGrind: Increased Productivity & Cost Efficiency

Conquer your gear manufacturing challenges with oelheld’s DiaGrind series. Increase grinding wheel and cutting tool life, reduce grinding burn and burrs, gain excellent air release properties, and achieve machine cleanliness – all with DiaGrind. Successfully used on gear hobbing, grinding and shaping applications.

Read More

Gear tool reconditioning on the Star NXT

The Star NXT linear CNC tool and cutter grinding machine sharpens both straight and spiral gash hob designs up to 8” OD x 10” OAL. The NXT also sharpens disk, shank and helical type shaper cutters, Scudding® and skiving cutters, and a wide range of round tools, making it a versatile tool room machine.

Read More