|

Get the freshest updates on gear technology

|

|

|

|

| Vomat Offers Filtration Technology for Metalworking Industry |

Choosing the right ultra-fine filtration system plays a key role in success in the metalworking industry. High-quality cooling lubricants and their efficient filtration are crucial for first-class product quality, cost-effectiveness and a smooth production process. The filter manufacturer Vomat from Treuen/Germany offers high-performance filter technologies for this purpose. Thanks to the flexible FA machine concepts, customized solutions can be implemented, e.g. with optional modules such as special cooling systems for temperature-optimized coolant filtration.

|

|

| Blaser Examines Every Chip in Detail in an Innovative Series of Tests |

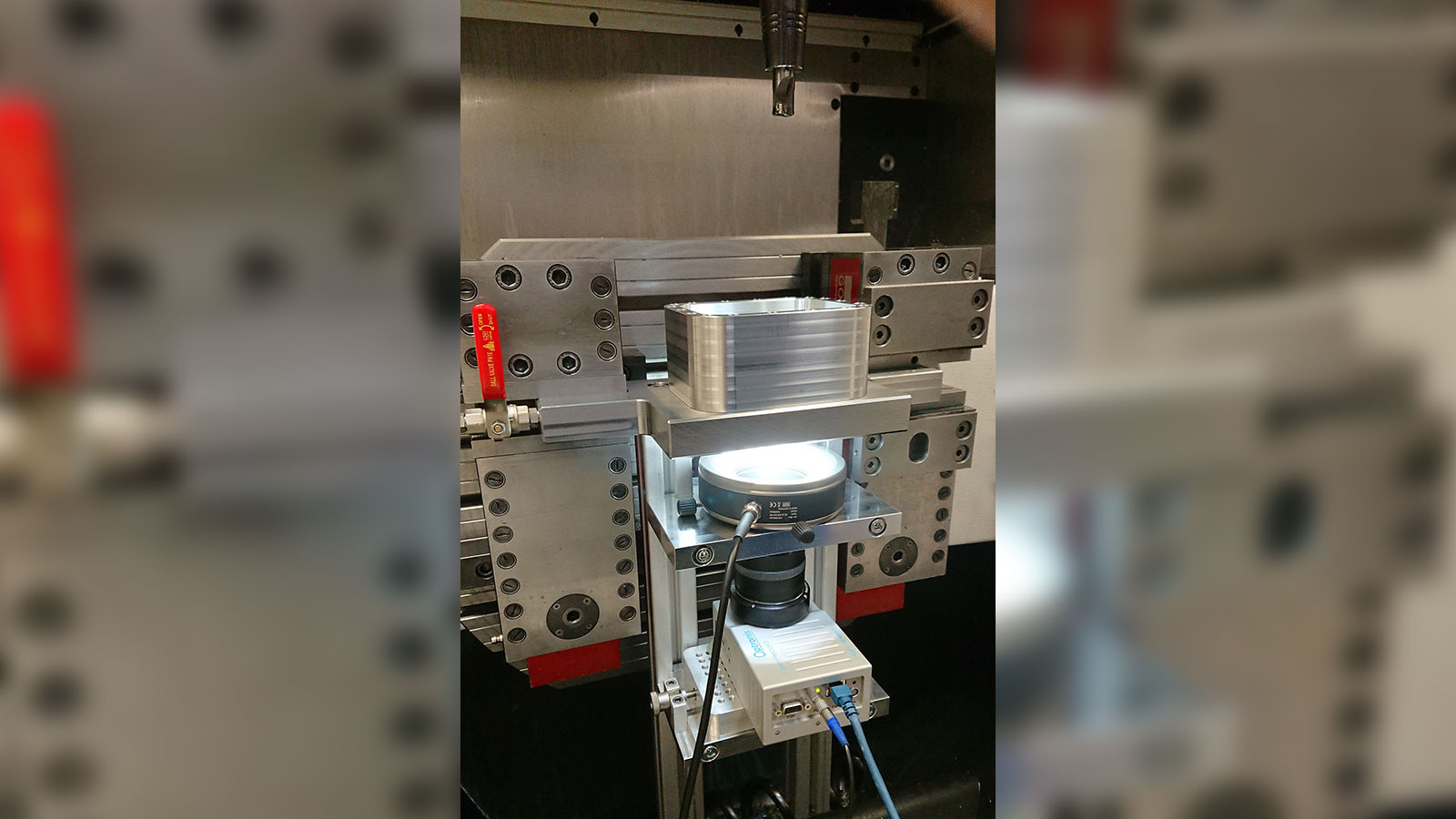

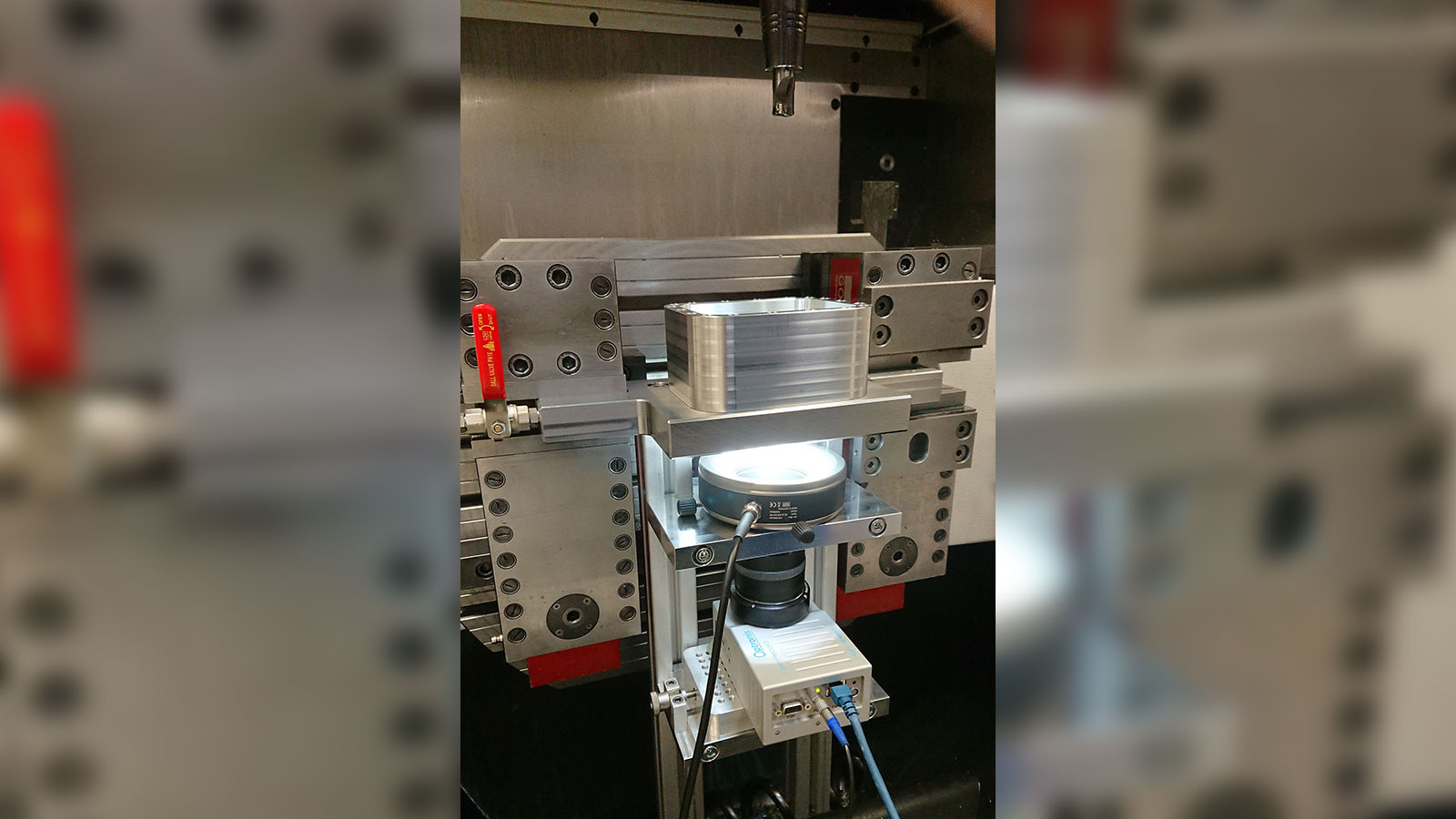

The macro high-speed recordings are impressive: Viewed in slow motion, a carbide milling tool removes a perfectly shaped brass chip. The Blaser Synergy 735 metalworking fluid becomes cloudy around the curling chip—exactly where the heat is greatest. It leaves an oil-like phase and thus forms an even more effective lubricating emulsion. In an extensive series of tests in the in-house Technology Center, the metalworking fluid experts from Blaser Swisslube analyze machining processes down to the finest detail. The principle: To achieve better metalworking fluids faster through expertise and data.

|

|

| High Production Carbide Hobs |

Star SU is a leading supplier of solid carbide hobs for gear tooth production. Our in-house carbide grades are available for cutting either green or hard materials and can be stripped and recoated. Application driven designs available in shell or shank configurations with multiple threads for maximum efficiencies.

|

|

|

| Optronic® Control no longer Optimal? Re-Control It! |

Machine Tool Builders can replace the Optronic CNC based controller on your Profile/Form grinder with NEW controls & drives. MTB includes on-board dressing & customized conversational programming at a fraction of the cost of a new machine. Your place or ours, we’re ready to pick up wrenches. Call us today!

|

|

|

| Our High Torque Gears Fill a Key Design Gap. |

We’ve helped top engineers tackle tough gearing problems for over six decades. Application industries include Robotics, Aerospace, Defense, Transportation, and Medical.

Learn how our gearing systems can be leveraged in your sector. Contact our engineers today at 320-762-7133

|

|

|

|

|

| Cut Waste. Boost Productivity. |

Pursue a sustainable future with Gasbarre’s multi-chamber vacuum furnaces. Unlike single-chamber designs, multi-chamber systems retain energy, cut emissions, and boost throughput. As low-carbon demand grows, these efficient furnaces are set to replace inefficient models—delivering cost savings, higher productivity, and a reduced environmental footprint.

|

|

|

| Join us for Gear Failure Analysis |

AGMA is hosting our Gear Failure Analysis course on November 4-6, 2025 in Chicago, IL! For more information such as dates and times and registration deadline, click on the link below.

|

|

|

|