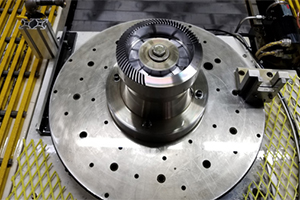

Teaming Up to Solve Bevel Gear Grinding Application Challenges

Fine pitch grinding from solid can be particularly problematic, as the typically narrow wheel tip width required to grind these gears makes it very difficult to achieve good balance between tip wear and productivity. To achieve the most efficient fine pitch bevel grinding solution, Norton| Saint-Gobain Abrasives (Worcester, MA) and Gleason Works (Rochester, NY) teamed up to evaluate, test and implement the latest, best abrasives application

Xstress DR45: Residual stress measurement in seconds.

Xstress DR45 is a X-ray diffractometer that delivers data faster than ever before. The speed and accuracy of the Xstress DR45 takes residual stress measurements beyond the laboratory and into the production line. All-new software with an intuitive, uncomplicated interface pairs with state-of-the art technology to offer seamless efficiency.

Read More

Gear Carburizing in Vacuum

Solar Atmospheres provides low pressure vacuum carburizing (LPVC) that significantly increases the surface hardness/strength of steel parts for improved friction and wear. Performing LPVC in a vacuum furnace eliminates oxygen and prevents IGO (intergranular oxidation) that is inherent in atmospheric carburizing, resulting in clean parts with less distortion reducing post process finishing operations, and costs.

Read More

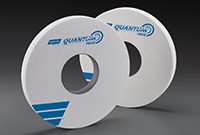

New Norton Quantum Prime Grain Revolutionizes Grinding Wheel Performance

A new, proprietary nano-crystalline ceramic grain offers unprecedented productivity gains in gear applications and more. The new Norton Quantum Prime grain delivers exceptionally high grinding efficiency and part quality, as well as significantly longer wheel life than traditional ceramic grains.

Learn More

Vacuum heat treating + oil quench solves demanding requirements

Gear heat treatment demands high metallurgical quality and repeatability, attributes that are best performed in vacuum. In addition, oil quenching permits fast, uniform quenching of dense, tightly packed loads, which improves throughput. The CaseMaster Evolution® vacuum furnace from SECO/VACUUM combines the best of both worlds.

Learn More

In-Place Machining Company Acquires OASIS Alignment Services

Exact Metrology recently announced that In-Place Machining Company (IPM) has acquired OASIS Alignment Services, LLC (OASIS) as part of a long-term growth strategy to expand reach and service offerings to customers and prospects across the U.S. and Canada.

Read More

Nidec Machine Tool Launches MVR-Hx Series

Nidec Machine Tool Corporation recently launched the MVR-Hx Series of double-column machining centers. Following the MVR-Cx series released earlier this month, the MVR-Hx series has been expanded to meet various needs in large parts machining.

Read More