Gear Skiving—A Step Changing Manufacturing Process Applicable to Multifunctional 5-Axis Machine Tools

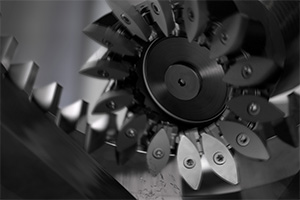

The main benefits of performing the gear skiving process on a multifunctional machine tool include smaller manufacturing cells, reduced capital expenditure, and the potential for an increase in dimensional accuracy of components, as the gear form can be generated in the same setup as the majority of other turned/milled features.

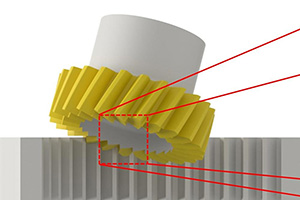

Investigation of Gear Surface Topography and Deviations in Gear Skiving Through Advanced CAD Modelin

The research presented in this paper extends the work done on CAD-based simulation approaches with an investigation of the surface topography of gears produced through gear skiving and the investigation of the cutting tool characteristics on the geometry of the produced gear. The study is complemented with the investigation of the cutting forces required in the machining process.

Helping Electric Vehicle Manufacturers Compete

“It’s competition,” said the American businessman John Mackey, “that forces companies to get out of their complacency.” We are seeing this in the global electric vehicle (EV) markets. Manufacturers must produce lighter and more compact EV transmissions from tough materials such as low-alloy steels—and those that rely on traditional manufacturing processes risk falling behind. Mats Wennmo, Global Automotive Transmission Manager at the metal cutting specialist Sandvik Coromant, explains why gear skiving is crucial for competitive manufacturing.

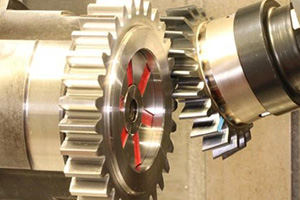

Design-optimized gear skiving tools perform better

Skiving is a complex and demanding procedure with no margin for error. Liebherr can use simulations to identify and exploit possible tolerances in the process kinematics in order to extend the tool life. This allows for optimized tools in terms of tool life and cost-effectiveness – without having to compromise on gear quality.

Read More

Seminar: Methods and Best Practices for Gear Process Engineering

November 8-10, 2022 - Don’t miss this three-day seminar featuring 8 Industry

Experts presenting comprehensive training for new and experienced gear

process engineers. The course features a full day on heat treat distortion. The

seminar is sponsored by Arvin Global Solutions and will be held at the Northern

Illinois University Facility in Naperville, Illinois.

Click here for More Information.

Join us for our Gear Materials course!

Our Gear Materials course taught by Ray Drago and Dale Weires, October 18-20 at AGMA’s National Training Center in Chicago. Learn about designing an optimum gear, the importance of coordinated efforts between all engineers, and gear-related problems.

Register Today!