[please visit our sponsor]

Nagel and Gehring Partner for Honing, Superfinishing and Electromobility Innovations

Nagel and Gehring recently shared innovative technologies during AMB 2022 including new standards in efficient honing, maximum flexibility in the superfinishing of flat, concave, and spherical surfaces, and efficient internal and external honing of workpieces.

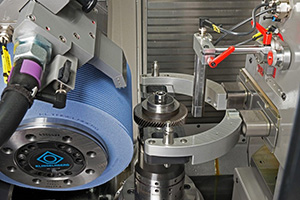

Klingelnberg Examines Gear Grinding Challenges Today

Within the last decade, hard finishing technologies become highly relevant. Increasing the power density of a gearbox requires precisely machined gears without heat distortions. Especially in noise-sensitive applications, both honing and grinding are often applied.

Over 60 years, engineers have relied on Spiroid® gearing.

From robotics to aerospace, our gears provide the most compact, highest torque and customizable solutions on the planet. It’s the perfect balance of torque, efficiency and ratio flexibility. Find out if Spiroid Gearing is the best fit for your next application. Schedule a call with our engineers today. 320-762-7133.

Grind Dry and Save!

Lower your overall cost per part by switching from wet to dry hard finishing of gears with an EMAG SU SG 160 SKY grinding machine. See reductions in energy costs, machine investments, consumables, waste disposal as well as environmental impacts and health risks for employees. Learn more.[please visit our sponsor]

Does your shop suffer from purchasing problems?

Poor purchasing practices can lead to all kinds of problems like jobs shipping late, decreased quality and increased costs. Read the 5 Ways to Modernize Your Manufacturing Purchasing whitepaper to bring your purchasing into the 21st century and get back on top.

Download >>

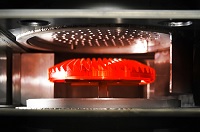

4D Quench Predicts & Controls Distortion

SECO/VACUUM's UniCase Master® single-piece flow vacuum furnace virtually eliminates all post-heat treatment costs associated with distortion. It takes parts from your machining center, heat treats them in vacuum, quenches using multiple high pressure gas jets as the part rotates (the 4th dimension) and automatically delivers them to the next manufacturing process.

Read More

Join us for Operator Precision Gear Grinding!

AGMA’s Operator Precision Gear Grinding class is scheduled for November 2-3 in Chicago at AGMA’s National Training Center. This is a great basic course for those new beginners to the gearing industry and gear grinding models will be used. We hope to see you there!

Register Today!