[please visit our sponsor]

Taking into Account the Production Methodology and Estimating the Influence of Manufacturing Quality

A multitude of different processes for manufacturing cylindrical gears are available. For pre-machining, processes such as hobbing, profile milling, shaping, broaching or skiving are available. Fewer processes exist for hard finishing, mainly generation grinding, profile grinding and gear honing. Gears are produced based on the tool geometry and process kinematics. The kinematic is calculated by the control software of the machine, using the theoretical gear data and the required tooth modifications. Usually, the design department designs a gear with little discussion about the production. If the production is outsourced, as is often the case nowadays, during the design phase usually no decision is taken as to who will produce the gears, or which process will be used.

Liebherr Offers Machine Training Center in Kempten

The Machine Training Center (MTC) of Liebherr-Verzahntechnik GmbH in Kempten offers bright training rooms equipped with the latest technology the world of gear making has to offer including an LC 280 gear cutting machine with ChamferCut device, an LGG 280 gear grinding machine and a WGT measuring machine.

Auction - World Renowned CNC Manufacturing Facility

Featuring (19) Gear Machines Including CNC Gear Shapers, Gear Grinders, Gear Hones, Gear Washers, & Gear Deburring Machines; (12) CNC Vertical Lathes, Turning Centers, and Machining Centers; (12) ABB Robots, (5) Hones, (2) Spline Rollers, (18) Presses, PLUS: CNC & Manual Grinders, CMM, Part Washers, Testing/Checking/Assembly Equipment[please visit our sponsor]

Low Pressure Carburizing of Gears

Solar Atmospheres provides low pressure carburizing (LPC) that significantly increases the surface hardness/strength of steel parts for improved friction and wear. Performing LPC in a vacuum furnace eliminates oxygen and prevents IGO (intergranular oxidation) that is inherent in atmospheric carburizing, resulting in clean parts with less distortion reducing post process finishing operations, and costs.

Read More

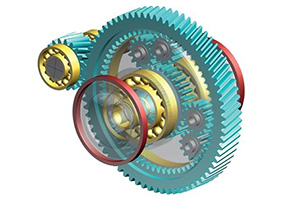

Gear grinding solutions for e-mobility

Gear manufacturers have to adapt their processes to meet the demands of new drive technologies, such as noise reduction and robustness. Liebherr has optimized various technological solutions to fulfill these demands. For example, generating grinding with dressing-free CBN grinding worms, topologically error-free grinding with targeted end relief, and noise excitation optimization.

Read More

Gear Machines in stock at Nidec Machine Tool America

Nidec’s Legendary Reliability is available for quick delivery. Nidec Machine Tool America has hobbers, shapers and gear grinders in stock and ready to get your production up to full speed. Call Scott Knoy at 248-756-5017.

Read More

Machine Tool Builders: Your One-Stop Shop

Take your production to the next level with Machine Tool Builders’ world-class lineup of new gear manufacturing technologies, featuring: horizontal and vertical hobbing, generative & profile grinding, chamfer/deburr & inspection, plus the industry-leading rebuilds, retrofits and service that we’ve built our reputation on since 1995.

Read More

Always on Top

Gearboxes in wind turbines are exposed to harsh conditions and extreme forces. As the market leader in this segment, Gleason is the standard for manufacturing high-precision gears for optimum power transmission and long-lasting reliability, saving replacement

and maintenance costs. Learn more at Booth E6007 in East Hall 6 at JIMTOF in Tokyo, Nov 8-13.

More Information

The future of manufacturing is here

Renishaw’s Roadshow is almost here! Join us to learn about our solutions to advanced manufacturing challenges faced by the automotive, aerospace, medical and electronics industries, as well as precision manufacturers and scientific/research analysis operations. The Roadshow is scheduled for November 2-3 (9AM to 5PM) at Renishaw’s Auburn Hills, MI location.

Register Today