[please visit our sponsor]

Feel the Burn

Heat Treat 2023 is the Heat Treating Society’s 32nd conference and expo for heat treating professionals featuring three days of face-to-face networking opportunities with approximately 200 heat treat exhibitors/companies. All the top heat-treating companies will offer the latest research and industry insights during more than 100 technical programs. This year’s show includes a VIP-guided industry tour, as well as student/emerging professionals initiatives, including free college student registration, Fluxtrol Student Research Competition, and the ASM Heat Treating Society Strong Bar Student Competition. Heat Treat 2023 is colocated with Motion + Power Technology Expo 2023 with access to additional exhibitors. The event takes place October 17–19, 2023 at Huntington Place in Detroit.

Motion + Power in the Motor City

The Motion + Power Technology Expo is a three-day show that’s designed for the gear and power transmission industry, representing the entire community of professionals involved in the life of a gear, gearbox or other power transmission device—from design to manufacturing, testing, heat treating and more. You can find the suppliers of the equipment to make gears as well as gear and gear drive manufacturers themselves, along with related suppliers of things like software, tooling, lubrication, bearings and more.

Last Chance to Reserve a Booth for MPT Expo

Motion + Power Technology Expo opens in just a few weeks. There’s still time to reserve a booth and showcase your power transmission solutions to the industry. Sign up within the next week and plan to meet with qualified buyers in Detroit.

Register Today

Visit SECS at MPT Expo

Since 1963 Secs, Inc. has offered an extensive line of standard gears which includes hub and hubless spur gears, anti-backlash gears, miter and bevel gears, worm gears and worms, helical gears, cluster gears and pinion shafts. We are equipped to provide standard parts, custom parts from your spec or other-source part number. All quantities of Standard Parts, Specials, and Long-Term Delivery agreements are available for quote. Visit us at MPT Expo Booth 2513.

Visit Us Online

100% In-Process Quality Inspection for Low Noise Transmissions

Today, manufacturers take about 30 minutes to inspect and analyze a gear for NVH gear noise analysis. Instead, the new GRSL Laser Inspection System with Advanced Waviness Analysis gauges, measures and analyzes one gear, depending on the measurement scope, in one minute, for up to 100% quality inspection of your production output.

More Information

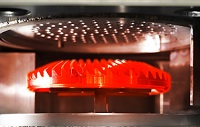

4D Quench Predicts & Controls Distortion

SECO/VACUUM's UniCase Master® single-piece flow vacuum furnace virtually eliminates all post-heat treatment costs associated with distortion. It takes parts from your machining center, heat treats them in vacuum, quenches using multiple high pressure gas jets as the part rotates (the 4th dimension) and automatically delivers them to the next manufacturing process.

Read More

Croix Gear Sharing Expanded Capabilities at MPT Expo

Croix Gear, a national leader in manufacturing bevel gears, will share expanded production capabilities for spiral, straight, hypoid, and Zerol bevel gears at the Motion + Power Technology Expo in Detroit, on October 17-19. Visit Croix Gear at Booth 3219 to learn how these updates can positively impact your business.

Learn More

Revolutionize gear production with Liebherr innovations

Discover cutting-edge advancements at the Motion + Power Technology Expo in Detroit, October 17-19. Liebherr Gear Technology and Automation Systems, Booth 2800, unveils the LC 400 M hobbing machine, WGT 400 measuring machine, skiving tools, SECLA segment arbor, and LHWebPlatform digitization solution. Elevate precision, quality, and productivity in gear manufacturing.

Read More