Profile Shift

The objective of this report is to determine the origin of the phrase “profile shift.” Several technical books, technical papers, and industrial standards were reviewed for nomenclature associated with profile shift. The phrase “profile shift” translates directly to the German term “Profilverschiebung,” which originated in the last quarter of the 19th century. At first, profile shift was used to avoid undercutting pinions with small numbers of teeth. Later, it was recognized that profile shift improved the load capacity of the gear mesh and extended the service life of manufacturing tools.

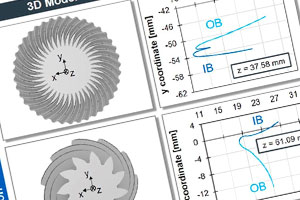

Process and Tool Design Optimization for Hypoid Gears with the Help of the Manufacturing Simulation BevelCut

In this paper, the mode of operation as well as the current scope of the manufacturing simulation BevelCut was presented. The cutting characteristics for an exemplary design were evaluated for both pinion and ring gear manufactured using face hobbing rolling and plunging. A relationship between the simulation results and cutting phenomena was established. Based on this relationship, corrective measures were deduced. The simulation results show a successful optimization of the tool and process parameters for the gear design. Thus, for the first time, a simulation-based tool and process optimization were conducted for face-hobbing processes.

For over 60 years, engineers have relied on Spiroid® Gearing.

From robotics to aerospace, our gears provide the most compact, highest torque and customizable solutions on the planet. It’s the perfect balance of torque, efficiency and ratio flexibility.Find out if Spiroid Gearing is the best fit for your application. Schedule a call with our engineers today at: 320-762-7133.

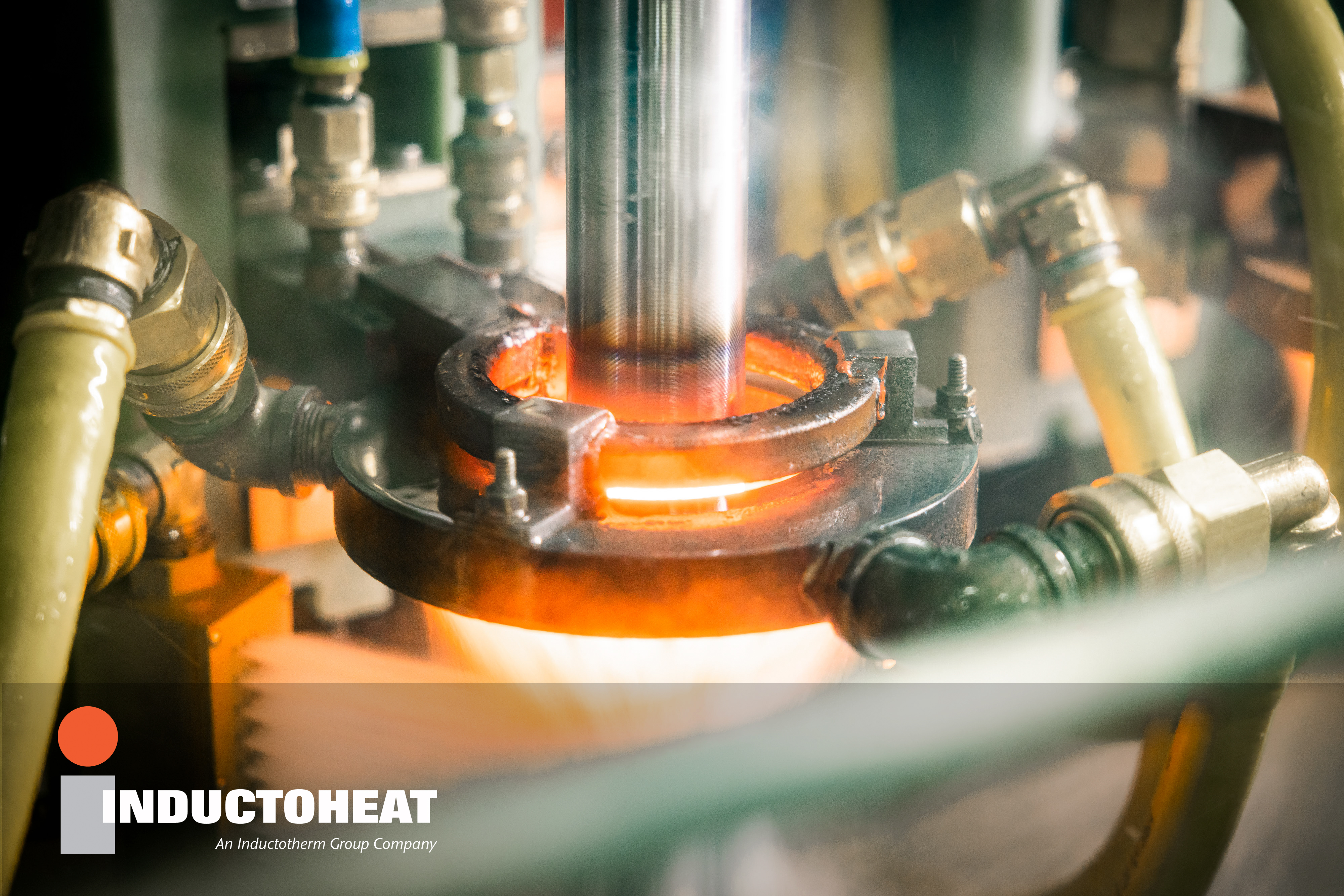

Zero Carbon Target?

Induction is an eco-friendly heating method, as it does not generate carbon during the heating process. The electrification of the automobile and the manufacturing goal of a zero-carbon target process makes induction the perfect solution for heat treating, tempering, brazing, forging, and shrink fitting.

Read More

For the widest range of bevel gears

Bevel Gears India offer one of the widest range of bevel gears internationally from 0.25” up to 60” for various applications in Gleason or Klingelnberg profiles. Offering straight and spiral bevels, hypoids, high ratio hypoid and CNC bevel grinding. See how the latest CNC bevel technology can benefit your programs.

Read More

Solar Atmospheres Now Offers Oil Quenching Capabilities

Solar Atmospheres provides low pressure carburizing (LPC) in vacuum to increase the surface hardness/strength of gearing for improved friction and wear. LPC delivers clean parts with less distortion reducing post process finishing operations, and costs. For lower hardenability alloys and/or to attain higher core hardness on gears, Solar now offers vacuum oil quenching!

Read More