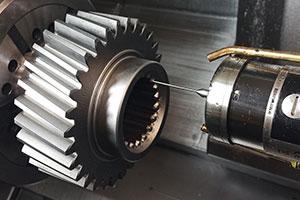

Hard Skiving of an Internal DIN5480 Spline—A Process Analysis

Due to developments in the field of cutting materials, machine technology, and process understanding, the process can now also be applied and used on universal machining centers.

Investing in Industry 4.0 for the Gear Manufacturer/Job Shop (Part 1)

Should this job shop buy a new CNC lathe with higher metal removal rates so the manual lathes department can be eliminated? Or should it buy a CNC turning center that combines the operations done on the CNC lathe and CNC mill? Or should it explore how to eliminate the shapers by using their CNC mills to cut the internal splines on some of their parts? Having observed the WIP in the three buildings that comprise this machine shop, the CNC lathes department is not the shop’s bottleneck.

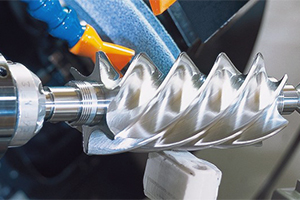

Versatile Profile Grinder for Gears, Worms & Splines

Grind spur, helical and crown gears, worms, splines, ball screws, rotors for air compressors and screws for hydraulic pumps on the EMAG SU’s G 375 H. Its customizable options can grind high-quality workpieces up to 15” diameter and 34.5” long.

Our High Torque Gears Fill a Key Design Gap.

For over six decades, we’ve helped top engineers tackle tough gearing problems. Application industries include: Robotics, Aerospace, Defense, Transportation and Medical.

Learn how our gearing systems can be leveraged in your sector. Contact our engineers today at 320-762-7133 for more information.

Download Case Studies Here>

DEVELOP THE HEAT TREATMENT WORLD WITH US

We Research And Develop:

- products

- technologies

- ourselves

- our customers

Read More

Engineering Excellence: Innovations Unveiled

Explore the real-world applications of engineering innovations in our webinar. Discover how Freudenberg’s cutting-edge solutions in oil seals are driving progress in gear manufacturing and beyond.

Register Now