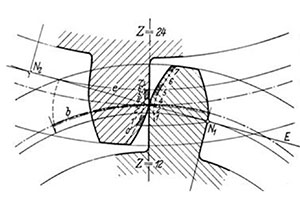

Profile Shift

The objective of this report is to determine the origin of the phrase “profile shift.” Several technical books, technical papers, and industrial standards were reviewed for nomenclature associated with profile shift. The phrase “profile shift” translates directly to the German term “Profilverschiebung,” which originated in the last quarter of the 19th century. At first, profile shift was used to avoid undercutting pinions with small numbers of teeth. Later, it was recognized that profile shift improved the gear mesh's load capacity and extended manufacturing tools' service life.

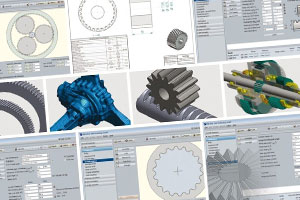

GWJ Technology Presents New Version of TBK Calculation Software

GWJ Technology GmbH has presented a new version of its desktop solution TBK with numerous enhancements, particularly in the field of gearing. In the latest version, the load capacity calculation according to DIN 3990 and ISO 6336 has been revised and expanded in the calculation modules for cylindrical gear pairs, planetary geartrains, 3- and 4-gear train systems and gear racks. It is now possible to individually specify additional factors such as the roughness and lubricant factor as well as the velocity or size factor. Furthermore, the calculation in the fatigue strength range has been improved.

Try the FVA-Workbench Drive Technology Software for Free

Unleash the power of drive development with the FVA-Workbench. Tap into over 50 years of groundbreaking research from the German Drive Technology Research Association (FVA) for modeling complete systems and optimizing gears, bearings, and shafts. With intuitive tools, advanced calculations, and interactive reports, the FVA-Workbench makes it easy to streamline your design processes and drive innovation forward.

Start your free trial today!

High Production Carbide Hobs

Star SU is a leading supplier of solid carbide hobs for gear tooth production. Our in-house carbide grades are available for cutting either green or hard materials and can be stripped and recoated. Application driven designs available in shell or shank configurations with multiple threads for maximum efficiencies.

Read More

Join us for Gear Systems Design for Minimum Noise

AGMA is hosting our Gear Systems Design for Minimum Noise on November 12-13 & 19-20, 2024 online! For more information such as dates and times and registration deadline, click on the link below.

Register Now