[please visit our sponsor]

Write for Gear Technology

Gear Technology's editors have released our 2020 Editorial Guidelines. This documents includes the list of topics we plan to cover throughout the coming year, along with deadlines and advice on how to get featured in our pages. We'd like to enlist some passionate, technically oriented individuals in our industry to help us create the content our audience needs! Contact an editor to get started today!We're looking for:

- Application Stories (Case Studies)

- Feature Articles

- Technical Articles

- Voices Column Editorials

- Product News

- Industry News

- Events

Get started by contacting Managing Editor Randy Stott today (wrs@geartechnology.com).

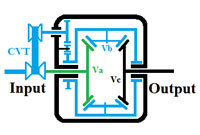

Introducing the NEW GEARBOX GENERATION - Licensing available

The new generation of gearboxes uses a differential.

- No more switching gears

- The motor can be kept running at constant speed, all the time

- Higher efficiency

- Even a small motor can produce a very high starting torque

- The system is reversible (dynamic braking)

- Cheaper to build

Read More

KAPP NILES Metrology - Check more gears!

- Faster with advanced KNM C5 CNC and Windows 10, 64-bit system

- Granite slides, air bearings, active spring damping, thermal comp

- Retracting tailstock and smart tooling for quick, convenient operation

- Smart design without compromise

- KNM 2X, 5X and 9X

Watch the Video

Spiroid Produces Greater Gear Torque in Less Space.

When failure is not an option, Spiroid Gears step in. Our gear solutions are depended on and used in nuclear power plants, commercial jets and national defense systems. We produce greater torque in less space with reduction flexibility and positive backlash control. Spiroid’s skew-axis, high torque gears enable world-class power density.

Read More

The Secret Is Out!

Better Than Broaching!

GMTA (German Machine Tools of America) has revealed the secret…new from Profilator…one machine that can be used for green machining, hard machining and finishing of internal gears in dry cutting processes…call us to arrange a demo.

Read More

We've Got Your Grinding Needs Covered

Removing heat and reducing friction during the metal grinding process is vital to increasing wheel life, maintaining workpiece geometry and achieving surface finish goals. The Benz team of metalworking specialists work with manufacturers to optimize each operation with the proper grinding fluid. BENZ GRIND is a great start.

Read More

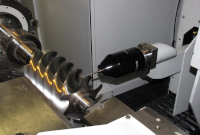

PTG Holroyd Offers Rotor Grinding Machine

The TG350E rotor grinding machine from UK-based Holroyd Precision is rapidly making a name for itself as the preferred choice among industrial refrigeration specialists globally.

Read More