Remanufactured Gear Machines and Quench Presses - Dixitech CNC at MPT Expo 2021

Dr. Devin Flowers, President of Dixitech CNC, talks about remanufactured gear machines and especially the niche the company has found in quench presses.

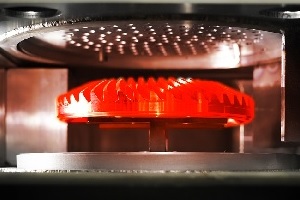

Heat Treat White Paper: Benefits of single piece flow & 4D quench

This white paper from SECO/VACUUM will show how quenching in 4 dimensions, where multiple high-pressure gas jets are applied to a rotating part in a single-piece flow process, can produce up to 1 million perfectly uniform gears per year. Learn how to control distortion and reduce waste in your heat treat process.

Excellent Gear Chamfer Quality and Lower Tool-Cost-Per-Part

With the new Genesis® 280HCD Gear Hobbing and Chamfering Machine, the many benefits of gear chamfering in parallel with hobbing are now available for the full range of automotive applications, including final drive ring gears and shafts, as well as job shop, industrial and light truck applications. Gleason’s Chamfer Hobbing process delivers excellent chamfer quality with lower tool-cost-per-part.

Read More

oelheld’s DiaGrind: Increased Productivity & Cost Efficiency

Conquer your gear manufacturing challenges with oelheld’s DiaGrind series. Increase grinding wheel and cutting tool life, reduce grinding burn and burrs, gain excellent air release properties, and achieve machine cleanliness – all with DiaGrind. Successfully used on gear hobbing, grinding and shaping applications.

Read More

High Production Carbide Hobs

StarSU is a leading supplier of solid carbide hobs for gear tooth production. Our in-house carbide grades are available for cutting either green or hard materials and can be stripped and recoated. Application driven designs available in shell or shank configurations with multiple threads for maximum efficiencies.

Read More

On-Spec and On-Budget, Trust Clifford-Jacobs

We use the highest-quality materials expertly engineered to fit each customer’s individual needs from standard to custom die forgings.

Our ready supply of raw materials and strategic location means that nobody is better equipped than Clifford-Jacobs to meet the needs of our customers, On-Time and On-Budget.

Read More

TCI Precision Metals Introduces Lights Out Materials

TCI Precision Metals recently announced support for lights out manufacturing with close tolerance materials that are Machine-Ready for Production (MRP) Guaranteed.

Read More

A3 Reports Strong Q3 Robot Orders

Strong robot sales in the third quarter of 2021 bring the total number of orders so far this year to nearly 29,000 units valued at $1.48 billion, the best numbers ever recorded for the North American robotics market.

Read More