[please visit our sponsor]

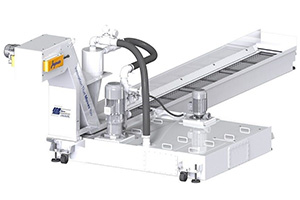

Jorgensen Launches Three New Systems to Optimize the Machining Process

Jorgensen Conveyor and Filtration Solutions announces the introduction of three new systems that will reduce labor and improve performance throughout the entire machining process. The new PermaClean Filtration System eliminates sludge build-up by adding optional agitation to the coolant collection tank. Eductor nozzles keep coolant in motion, suspending chip particulates and preventing them from settling. Collection tanks equipped with PermaClean combined with cyclonic filtration are virtually maintenance-free and significantly reduce the labor required for frequent tank cleaning.

Kyzen to Exhibit Metalnox Alkaline Cleaners with Corrosion Inhibitors at FABTECH 2022

Cleaning and then protecting metal parts is traditionally done in two stages with two different chemistries; however, there are products with the corrosion inhibitor built-in to simplify the process while providing pristine parts. Visit Kyzen at FABTECH to learn how its product offerings for clean, rust-free parts can save both time and money.

oelheld’s DiaGrind: Increased Productivity & Cost Efficiency

Conquer your gear manufacturing challenges with oelheld’s DiaGrind series. Increase grinding wheel and cutting tool life, reduce grinding burn and burrs, gain excellent air release properties, and achieve machine cleanliness – all with DiaGrind. Successfully used on gear hobbing, grinding and shaping applications.

Read More

Connecting the dots – Power Skiving with esco

Power Skiving is a very productive technology, but with plenty of challenges involved. The key to success is knowledge and full control of the entire chain from the gear to the cutting tool and the process. For this, esco offers a complete software platform: ePP is the enabler for efficient implementation and use of this cutting-edge technology.

Register and learn

The First Choice in Gas Nitriding Technology – ZeroFlow Plus

Gas nitriding is subject to many variables such as temperature, atmosphere, surface condition of the parts, Kn control and more. SECO/VACUUM’s ZeroFlow control process makes nitriding easier and more repeatable by achieving high surface hardness, improved wear, longer fatigue life, better corrosion resistance, and no follow-up machining. Click to learn more about the latest on nitriding technology.

Read More