[please visit our sponsor]

Marposs Announces the Digital Platform, MAINDO

Marposs has announced MAINDO, its new digital platform that integrates Marposs monitoring, measuring, testing or other manufacturer device/solutions throughout the entire production process, combining quality and process into a holistic production monitoring view. Marposs modular software systems, comprised of brands such as Blulink, MG, Brankamp, Artis, S&K, enable a direct network connection between a production level system, a process monitoring system or a PLC terminal and the production control and quality management systems with higher-level company systems like ERP, PLM, MES, etc. The MAINDO platform offers improved production quality, reduced costs, traceability, and remote data accessibility.

Taking into Account the Production Methodology and Estimating the Influence of Manufacturing Quality

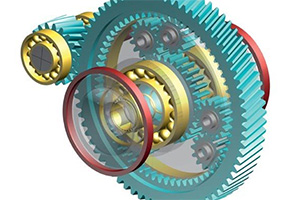

This paper describes the basis for, and results from, a project that investigated the influence of quality on the resulting transmission error and the excitation force in the gear meshing. To achieve this, a sinus-shaped waviness is applied to the theoretical ideal tooth flank. The amplitude, length, and initial value of the waviness can be modified. This modification can be applied in both the profile or flank line direction, individually, or both at the same time. The changes in transmission error, excitation force, and other fundamental influences on the causes of vibration are then evaluated to obtain a result. The changes in transmission error and other values that occur can then be displayed and used to forecast the effect of the quality on the NVH performance. The application of this method to some current gear units is shown and discussed.[please visit our sponsor]

The Power of the Smart Loop

KISSsoft Gear and Transmission Design Software now features powerful analysis tools for gear manufacturing and inspection, promoting close collaboration and data exchange between engineers in design, manufacturing and quality assurance. Keep gear quality at consistently high levels and minimize scrap with Smart Loop manufacturing.

More Information

Digital Metrology Introduces TraceBoss Software for Portable Roughness Gages

Digital Metrology Solutions, provider of measurement software, consulting, and training, has introduced the TraceBoss software package for portable roughness gages.

Read More

Shell Signs Agreement to Acquire ECL Business of PANOLIN

Wholly-owned subsidiaries of Shell plc (“Shell”) in Switzerland, the UK, US and Sweden (Shell (Switzerland) AG, Shell U.K. Limited, Pennzoil-Quaker State Company and Shell Aviation Sweden AB) have entered into agreements to acquire the Environmentally Considerate Lubricants (ECLs) business of the PANOLIN Group.

Read More