GWJ Technology Celebrates 20 Years of eAssistant Software

A good 20 years have passed since the web-based calculation software eAssistant saw the light of day in the digital world. The software is probably the oldest commercial online solution for the design, recalculation, and optimization of machine elements such as shafts, bearings, shaft-hub connections, gears, bolted joints, springs, etc. The calculations are based on internationally accepted standards and guidelines as well as technical literature.

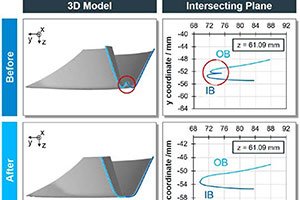

Process and Tool Design Optimization for Hypoid Gears with the Help of the Manufacturing Simulation BevelCut

In this paper, the mode of operation as well as the current scope of the manufacturing simulation BevelCut was presented. The cutting characteristics for an exemplary design were evaluated for both pinion and ring gear manufactured using face hobbing rolling and plunging. A relationship between the simulation results and cutting phenomena was established. Based on this relationship, corrective measures were deduced. The simulation results show a successful optimization of the tool and process parameters for the gear design. Thus, for the first time, a simulation-based tool and process optimization were conducted for face-hobbing processes.

The key to greater transparency: LHWebPlatform

Gear cutting technology manufacturer Liebherr offers a unique platform of interfaces, data profiles and web apps for customized digitization solutions. It monitors in detail what, when, where, how and in what time something was manufactured. Evaluations and reports present essential indicators. It creates transparency for productions – and transparency creates productivity.

Read More

For the widest range of bevel gears

Bevel Gears India offer one of the widest range of bevel gears internationally from 0.25” up to 60” for various applications in Gleason or Klingelnberg profiles. Offering straight and spiral bevels, hypoids, high ratio hypoid and CNC bevel grinding. See how the latest CNC bevel technology can benefit your programs.

Read More

Ceratizit Brings Customers UP2DATE with Advanced Cutting Tooling Solutions

In a direct response to evolving technologies and customer needs, Ceratizit releases the semiannual UP2DATE catalog of product developments and enhancements. The fall 2023 edition features three new products designed to provide Ceratizit customers with robust performance as well as reliable, precise, and cost-effective tooling solutions.

Read More