Closed Loop for Gears: Some Case Studies

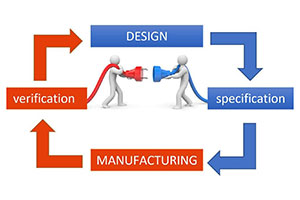

The goal of this paper is to help the reader improve the documentation and performance of bevel, cylindrical, and worm gears. The closed loop is an improvement in the manufacturing process of gears, which connects design and production in a two-way manner. A necessary condition for its adoption is an awareness that specification and verification must also be connected. You cannot request what you cannot measure. The measurement process must be defined in a clear, unambiguous way, just as the measurements to be taken already are.

Seco Propels Manufacturing with Smart Software and Actionable Intelligence

In the fast, cost-effective, sustainable future, smart software is paving the way to optimized production and improved decision-making. Digital technology and smart software have already transformed the machining industry with unprecedented access to actionable data for better results in less time. With a wealth of data generated from production processes of all kinds, shops need to understand how to use that data to their advantage. Now, progressive manufacturers can move toward even greater benefits with software that fulfills the promises of Industry 4.0.

Game Changer: Hamai N70 Horizontal Hobbing Machine

The Hamai N70 Series offers the worldclass speed, accuracy and dry hobbing productivity you need for fine pitch and super fine pitch hobbing– at a price you can afford. Models equipped with Fanuc 31i series CNC, direct drive and torque motor tables and hob head with 6000 RPM max; available for parts as large as 70 mm diameter x 200 mm long tooth sections max 2.5 Module. With or without automation.

Only from Machine Tool Builders

A reliable partner for power transmission critical gears and bevel sets

CATTINI, a leading Italian gear and bevel sets manufacturer with one of the broadest custom gear production capabilities in the industry, is now proud to be serving the Americas. Many multi-national heavy-duty vehicle and machinery OEMs have been choosing Cattini for years.

Read More

Ceratizit Brings Customers UP2DATE with Advanced Cutting Tooling Solutions

In a direct response to evolving technologies and customer needs, Ceratizit releases the semiannual UP2DATE catalog of product developments and enhancements.

Read More