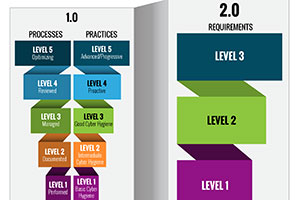

Forest City Gear Attains Level 2 CMMC 2.0 Compliance

Forest City Gear has updated its technology infrastructure and policies in compliance with Level 2 Cybersecurity Maturity Model Certification (CMMC) 2.0. The CMMC program ensures the protection of federal contract information and controlled unclassified information for suppliers within the U.S. Department of Defense’s supply chain. Through self-assessments aligned with NIST SP 800.171, Forest City Gear policies have proven to meet the 110 practices required for CMMC 2.0 compliance.

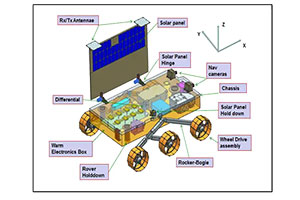

Bevel Gears India's Role in the Chandrayaan-3 Moon Landing Mission

On August 23, 2023 at 12:32 UTC, India’s Chandrayaan-3 mission made a successful landing on the southern part of the moon near the crater Manzinus. After carrying out all of the Indian Space Research Organization (ISRO)–planned investigations and explorations on the lunar surface and before the start of the two-week lunar night, the Pragyan rover was put into sleep mode on September 2nd, 2023, and the Vikram lander on September 4th. We were able to catch up with Mushtaq Jamal, vice president of engineering and business development at Bevel Gears India Pvt Ltd (BGI), to discuss BGI's role in this monumental achievement for India.

Gear tool reconditioning on the Star NXT

The Star NXT linear CNC tool and cutter grinding machine sharpens both straight and spiral gash hob designs up to 8” OD x 10” OAL. The NXT also sharpens disk, shank and helical type shaper cutters, Scudding® cutters, and a wide range of round tools, making it a versatile tool room machine.

Read More

Vacuum Gas Nitriding: Gears

Vacuum gas nitride processing from Solar Atmospheres can significantly increase the fatigue strength and service life of your parts. Benefits include case depths up to 0.025” and improved wear and anti-galling properties due to a 40 - 70% increase in surface hardness. Corrosion resistance is increased through nitrogen-enrichment.

Read More

PV315/630 SkiveLine – Multifunctional PITTLER SKIVING machine

Modern gear skiving machine with flexible multifunctional head, tool magazine, y-axis, and original PITTLER SKIVING

software. This machine concept enables the flexible production of your workpieces.

Pittler SkiveLine - Entdecke Pittler Skiving

Technology for Gear Solutions

Miba Sinter Group is the technology leader in powder metal applications offering a wide variety of production processes. Semi-finished (near-net) blanks finalized by partner gear manufacturers deliver reduced machining time, waste, and costs. Net-shape spur and helical gears with NVH performance, high strength and precision, and cost-optimized design and production.

Read More

Stock machines = NIDEC Machine Tool America

Don’t wait to be more productive. NIDEC Machine Tool America has stock machines available for nearly instant delivery. Hobbers, shapers, gear grinders and the new CF26A chamfer machine are available NOW. Need financing? Let us help. Call Scott Knoy today at 248-756-5017.

Read More

For over 60 years, engineers have relied on Spiroid® Gearing.

From robotics to aerospace, our gears provide the most compact, highest torque and customizable solutions on the planet. It’s the perfect balance of torque, efficiency and ratio flexibility.

Find out if Spiroid Gearing is the best fit for your application. Schedule a call with our engineers today at: 320-762-7133.

Download Case Studies Here >

PDS Offers Reliable and Cost-Effective Spindle Repair

PDS provides manufacturers with better-than-new spindle rebuilds and repairs (within 1 micron) for precision machining applications. Since 1996, PDS’ factory-trained engineers and technicians have successfully rebuilt and globally supported more than 40,000 spindles. Save up to 50% of a new spindle replacement with PDS precision spindle repair! Call us at 704-922-1206.

Or Visit

Starrett Hosts Successful Manufacturing Day for Students, Community

The Starrett event featured guided tours of its headquarters facility and highlighted a range of exciting opportunities in manufacturing innovation and technology in the following areas: CNC programming, robotics automation, 3D modeling, drafting, Industry 4.0, and training and development.

Read More

Marposs Announces “Marposs Care” After Sales Service

Marposs, a global leader in measurement, inspection, and test technologies has announced its Marposs Care after-sales service. The service agreements for Marposs Care focused on preventive maintenance, calibration, customer training, and process improvement, and supported each area with a team of specialized engineers.

Read More