Tooth Root Bending Strength of Shot-Peened Gears Made of High-Purity Steels up to the VHCF Range

Standardized methods, like AGMA 2001-D04 or ISO 6336 for the calculation of the load carrying capacities of gears are intentionally conservative to ensure broad applicability in industrial practice. However, new applications and higher requirements often demand more detailed design calculations nowadays; for example: long operating lives in wind power gearboxes or fewer gear stages and higher speeds in e-mobility applications result in higher load cycles per tooth in a gearbox.

IGS to Increase Wind Gearbox Torque Density

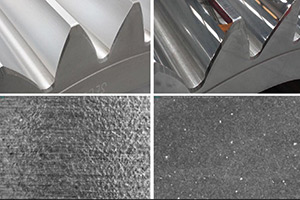

To increase cost efficiency in wind turbines, the wind industry has seen a significant rise in power density and an increase in the overall size of geared components. Current designs for multimegawatt turbines demand levelized cost of energy (LCOE) reduction, and the gearbox is a key part of this process. Since fatigue failures nearly always occur at or near the surface, where the stresses are greatest, the surface condition strongly affects the gear life. Consequently, an improved surface condition effectively avoids major redesign or increased material cost due to an increase in part size. Additional finishing methods such as shot peening (SP) and superfinishing (SF) significantly increase the gear load capacity, but these effects have not yet been adequately considered in the current ISO 6336 standard or in any other gear standards. The combination of SP followed by SF will be described here as an “improved gear surface” (IGS).

Over 60 years, engineers have relied on Spiroid® gearing.

From robotics to aerospace, our gears provide the most compact, highest torque and customizable solutions on the planet. It’s the perfect balance of torque, efficiency and ratio flexibility.

Find out if Spiroid Gearing is the best fit for your application. Consult our engineers directly today at 320-762-7133.

VISIT OUR CASE STUDY LIBRARY

KISSsoft Offers Service Pack 2 from Current Software Release

KISSsoft has released a more comprehensive functionality with the Service Pack 2 from the current KISSsoft Release satisfying the increasing demand in key industries. This software supports scripts for a variety of tasks, such as creating custom user interfaces, automating report generation, and exporting data.

Read More

Join us for Analytical Gear Chart Interpretation

AGMA is hosting our Analytical Gear Chart Interpretation on January 29, 2025 online! For more information such as dates and times and registration deadline, click on the link below.

Register Now