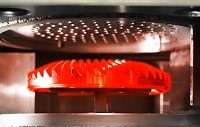

Heat Treat White Paper: Benefits of single piece flow & 4D quench

This white paper from SECO/VACUUM will show how quenching in 4 dimensions, where multiple high-pressure gas jets are applied to a rotating part in a single-piece flow process, can produce up to 1 million perfectly uniform gears per year. Learn how to control distortion and reduce waste in your heat treat process.

CUMI’s New Generation of Comprehensive Gear Grinding Solutions

CUMI’s design engineers have come up with a series of innovations for its Gear Grinding portfolio, with a succession of new generation engineered ceramic grains, that can match the efficiency demands of the modern and advanced grinding process, while providing the stringent surface finish on the gear work piece.

Advanced Automation for Heat Treat Production Lines

ECM ADVANCED AUTOMATION is the ideal solution for integrating & managing leading-edge robotic technology for your production line. Automate an existing or new heat treat system to assure a more reliable process from part sorting & load building to loading/unloading in an ECM vacuum furnace or peripheral equipment.

262.605.4810

www.ecm-usa.com

Read More

Xstress DR45: Residual stress measurement in seconds.

Xstress DR45 is a X-ray diffractometer that delivers data faster than ever before. The speed and accuracy of the Xstress DR45 takes residual stress measurements beyond the laboratory and into the production line. All-new software with an intuitive, uncomplicated interface pairs with state-of-the art technology to offer seamless efficiency.

Read More

Call for Papers: Abstracts Due January 14

Get your gear research published and presented at the Fall Technical Meeting in 2022.

Read More