[please visit our sponsor]

Tooth Root Bending Strength of Shot-Peened Gears Made of High-Purity Steels up to the VHCF Range

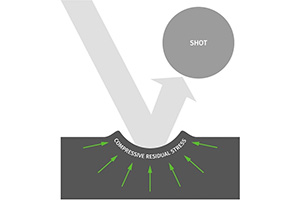

One approach to strengthen the tooth root of gears is to shot-peen the tooth root fillet. This results in higher compressive residual stresses in the tooth root area and can lead to a higher tooth root bending strength. However, a drawback is that in the VHCF range, crack initiation can often occur from below the surface at a nonmetallic inclusion. Consequently, a working hypothesis is: the higher the cleanliness, the fewer and smaller-sized the nonmetallic inclusions in the material will be, and therefore the higher the tooth root load carrying capacity of case-hardened, shot-peened gears. This working hypothesis is verified in the framework of this publication.

Nondestructive Evaluation of Stresses and Stress-Related Defects in Gears

There are a variety of methods to verify the shot peening process including the Almen strip test, visual analysis including the use of tracer dyes, and direct measurement of induced stresses. It is the latter method, measurement of induced stresses, which provides the only true objective measure which can be compared to expected values from the design and modeling phases. The best and most standardized method for the measurement of stresses is X-ray Diffraction (XRD).[please visit our sponsor]

2022 Gear Technology Buyer's Guide

The 2022 Gear Technology Buyer's Guide was compiled to provide you with a handy resource containing the contact information for significant suppliers of machinery, tooling, supplies and services used in gear manufacturing.

Read More

JTEKT Introduces New High-Productivity Silicon Wafer Disc Grinder

JTEKT recently demonstrated a new double-disc horizontal grinder that simultaneously grinds both sides of silicon wafers to +/- 1 micron from as-sliced condition. The DXSG320 performance represents a massive improvement in accuracy and productivity over the single-spindle vertical grinders common in the chip industry today which grind to 3-4 microns, according to the company.

Read More

Jorgensen Partners with Will-Fill on Coolant Management System

As of November 1, Jorgensen Conveyor and Filtration Solutions has entered into a partnership with Will-Fill, a manufacturer of fully automatic coolant monitoring and managing systems. The strategic partnership allows Jorgensen to offer customers complete and worry-free coolant management systems, such as the company’s recently launched PermaClean, that provide both filtering and measuring capabilities for an all-in-one solution.

Read More