[please visit our sponsor]

The Afterglow of Furnaces North America 2022

Furnaces North America 2022 (FNA 2022), presented by the Metal Treating Institute (MTI), in partnership with its media partner, Heat Treat Today, is the heat-treating industry’s go-to event every other year. FNA 2022 attracted attendees from across North America, including Fortune 500 companies.

Seeking Metallurgy and Heat-Treating Experts

The AGMA Aerospace Gearing committee is seeking new committee members to revise AGMA 926-C99, Recommended Practice for Carburized Aerospace Gearing. Specifically, metallurgy and heat-treating experts are needed. This information sheet recommends material case properties, microstructure, processing procedures, and other critical parameters for carburized aerospace gears. Due to the unique requirements of aerospace gearing, such as typically smaller lot sizes, demands for higher precision, and stringent quality requirements, this information sheet aims to provide deeper, aerospace-specific information than other already published metallurgical specifications such as AGMA 923, Metallurgical Specifications for Steel Gearing or AMS2759/7, Carburizing and Heat Treatment of Carburizing Grade Steel Parts.

Nitrex Including in the "American Dream" Amazon and Bloomberg Series

Nitrex Metal Inc. (“Nitrex”) is pleased to announce that it has been selected for the “American Dream” series airing on Bloomberg and Amazon Prime. The series explores the inspiring entrepreneurial stories of the men and women who founded and built incredible companies from the ground up. The feature found here, showcases the company as an industry pioneer who has led with innovation and hard work to become a leader in the surface treatment industry and the only provider of fully integrated surface treatment solutions and technologies.

Low Temperature Process Options to Reduce Gear Distortion in Thermal Processing

Ferritic Nitrocarburizing (FNC) and Nitriding improve wear, corrosion, and fatigue properties by processing in furnaces at lower temperatures while minimizing distortion. Learn more from Ben Bernard at Surface® Combustion, Inc.[please visit our sponsor]

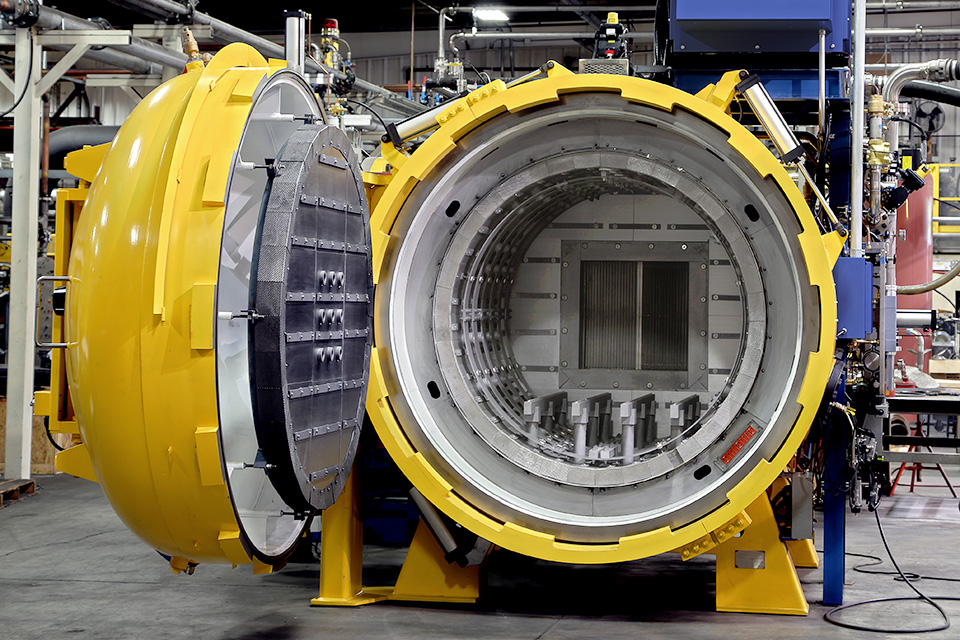

Solar Atmospheres Now Offers Oil Quenching Capabilities

Solar Atmospheres provides low pressure carburizing (LPC) in vacuum to increase the surface hardness/strength of gearing for improved friction and wear. LPC delivers clean parts with less distortion reducing post process finishing operations, and costs. For lower hardenability alloys and/or to attain higher core hardness on gears, Solar now offers vacuum oil quenching!

Read More

Built-for-Stock—Fast Delivery of UBQ Batch Furnace

AFC-Holcroft's innovative Built for Stock program offers us the ability to deliver equipment weeks or months earlier than typical build-to-order delivery. Best of all, there is no extra cost for this accelerated delivery. This program features popular equipment such as batch furnaces, EZ endothermic gas generators, and support equipment.

Read More

1st Choice Nitriding technology from SECO/VACUUM

SECO/VACUUM’s retort nitriding furnaces are available in more standard sizes and types than any other manufacturer. In addition to Nitriding, they are also used for Ferritic Nitrocarburizing (FNC) with post oxidation. SECO/VACUUM’s patented ZeroFlow® control technology with vacuum purge assures optimum results at low operating costs. Click to learn more.

Read More

High Pressure Quench Vacuum Carburizing Furnaces

Get fast, forceful gas cooling with Solar Manufacturing’s IQ series of vacuum carburizing furnaces. It’s high performance internal quench system with direct-exit, sliding radiation baffles is the least restricted gas flow path on the market for superior hardening at quench pressures up to 20 bar.

Contact us to learn more about our vacuum furnace ingenuity.

P: 267.384.5040

Learn More

ECM Heat Treat Robotics & Advanced Automation

Break the barrier from FURNACE SYSTEM AUTOMATION to ADVANCED HEAT TREAT ROBOTICS. Incrementally upgrade with ECM robotics specific to heat treating to ensure consistent production flow and managed labor expenses. Automate existing/new furnace systems with leading-edge technology (including washers, tempers, cryos…) for efficient part sorting, workload assembly/disassembly & AGV transport.

Read More

Successful Tool Tests with VBN’s Vibenite Followed by License Agreement with ANAJ

Tool materials that noticeably improve performance and lifetime—that is what defines the alloys of the Swedish company VBN Components AB. VBN has always focused on hard and wear-resistant materials that are additively manufactured, and today offers four steels and one cemented carbide under the Vibenite brand.

Read More