Custom-Fit Robot Solutions Ensure Fast Parts Flow in Production

Production solutions with robotic automation are on the rise: With their help, a fast and low-manpower flow of parts can be established within a site—thus reducing unit production costs and increasing production reliability and quality. In this example, EMAG links pick-up machine technology with highly individual robot solutions designed within the requirements of the workpiece and the production process. What are the important details?

The Inside Track on Automation, Robotics and Motion Control

The manufacturing sector has always invested in training and education, but something feels different in 2023. ABB has invested more than $22 million in robotics and will continue to prioritize education in the future. “Businesses in the future will need employees with experience in applying automation to perform a variety of processes,” said John Bubnikovich, US Country Lead Robotics & Discrete Automation, ABB Robotics. “As robots become more prevalent in factories, warehouses, and other environments, there will be an increase in partnerships between robot OEMs, system integrators, manufacturers, and educators to provide people the necessary skills for an automated future."

Thinking About Buying a New Hobber?

EMAG has a Koepfer K 300 horizontal hobbing machine with a built-in loading system in stock – perfect for hobbing shafts up to 12” long and gears up to 7.5” in diameter. Machine wet or dry.

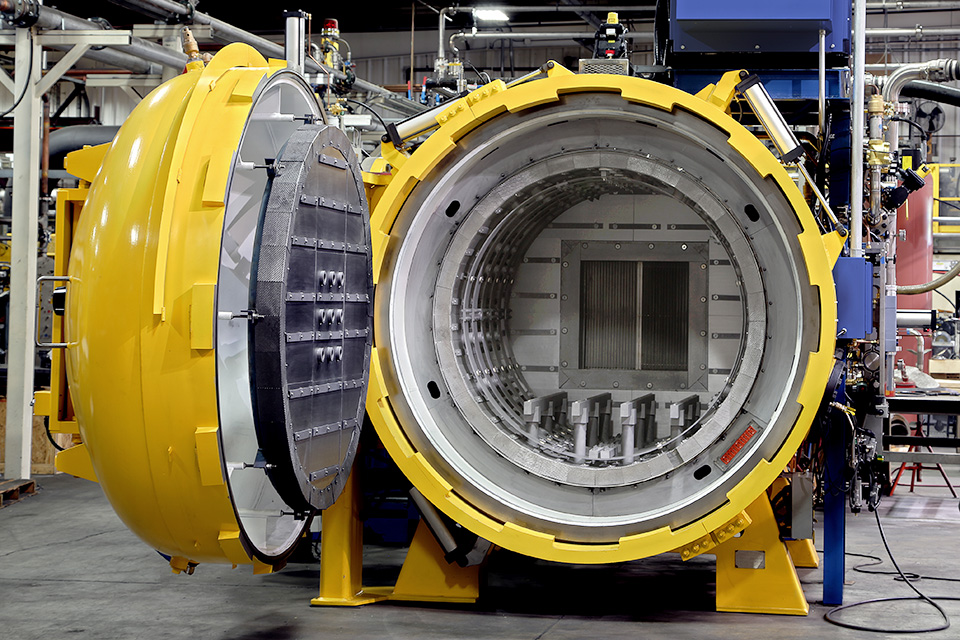

High Pressure Quench Vacuum Carburizing Furnaces

Get fast, forceful gas cooling with Solar Manufacturing’s IQ series of vacuum carburizing furnaces. It’s high performance internal quench system with direct-exit, sliding radiation baffles is the least restricted gas flow path on the market for superior hardening at quench pressures up to 20 bar.

Contact us to learn more about our vacuum furnace ingenuity.

P: 267.384.5040

Contact Us Now

SH410: The Vertical Hobbing Game Changer

The SMG SH410 vertical hobbing machine from MTB delivers worldclass speed, accuracy and

productivity for every job – at a highly affordable price. For parts as large as 410 mm diameter. With custom packages that include options for automation and on-board chamfer/deburring; provisions for extra-long shafts to 650 mm; and even hard skiving. Compact, highly rigid, for wet or dry hobbing.

Read More

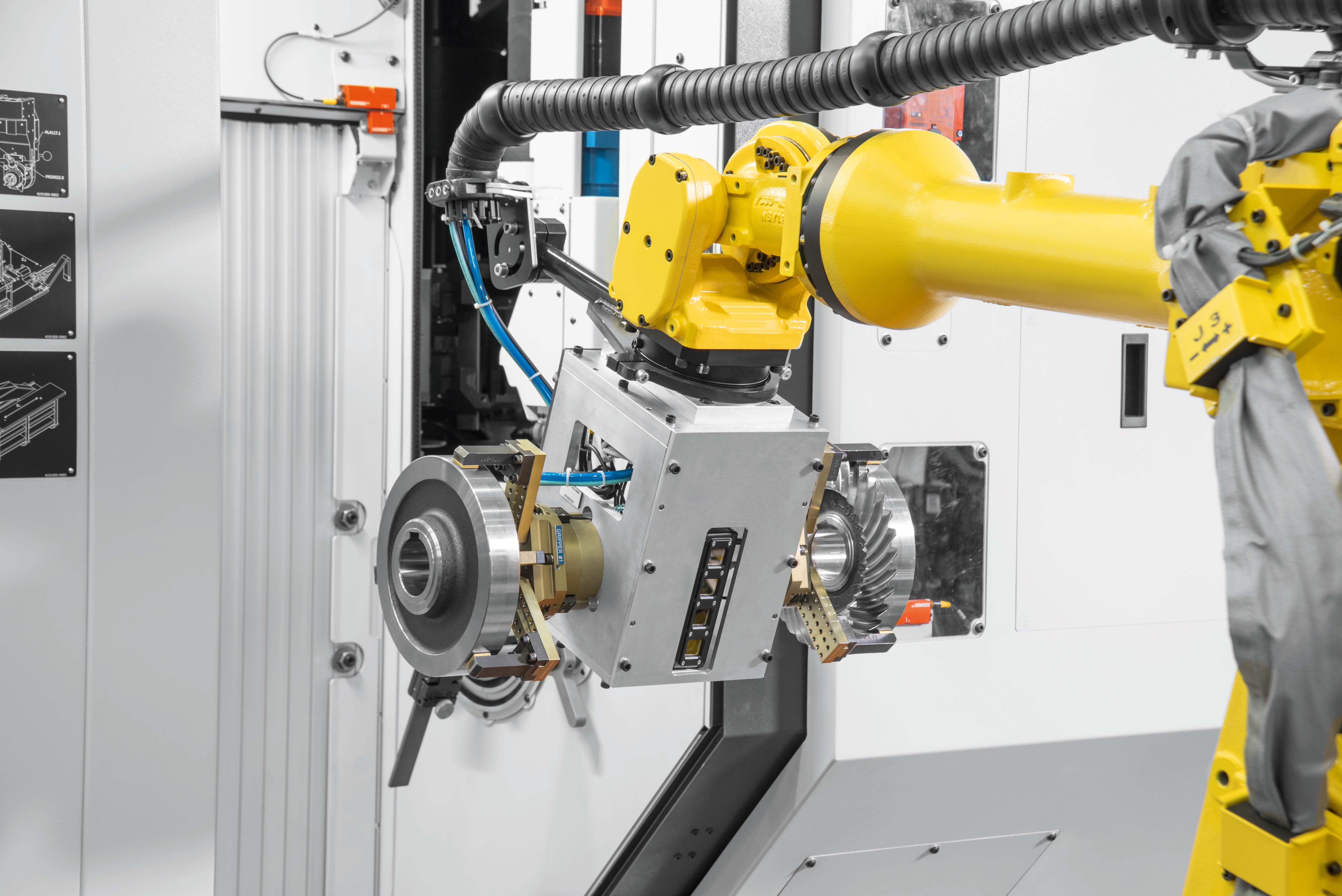

Precision Automation for Large Parts Handling

New Gleason Automation for load/unload of larger parts speeds throughput, optimizes the process flow – and lifts the burden off the machine operator. The AR Series uses advanced vision guidance to ID the part and ensure proper orientation before loading it into the machine, even if it arrives without precise location directly from dunnage. Easily integrated with pre-and post-processes such as part washing, deburring, inspection and marking.

See It In Action

Heat Treat Robotics & Advanced Automation with ECM

Advance your heat treat operation in the new year with ECM ROBOTICS. Take advantage of consistent & efficient cycles with reduced labor costs & instability. Automate your operation (including washers, tempers, cryos…) with leading-edge technology for part sorting, workload assembly/disassembly & AGV/AMR transport.

NEW VIDEO: https://bit.ly/ECMRobotics

Read More

Stock machines = NIDEC Machine Tool America

Don’t wait to be more productive. NIDEC Machine Tool America has stock machines available for nearly instant delivery. Hobbers, shapers, gear grinders and the new CF26A chamfer machine are available NOW. Need financing? Let us help. Call Scott Knoy today at 248-756-5017.

Read More

2024 Fall Technical Meeting Call for Papers | Abstracts Due 19 January 2024

The 2024 Fall Technical Meeting (FTM) will be in Chicago, IL, from October 7–9. We encourage gear industry experts and professionals to submit an abstract. All abstracts must be completed and submitted in full by January 19, 2024.

Learn More