Nidec Machine Tool America appoints Todd Hughes as West Coast Sales Manager

Todd Hughes is now the Regional Sales Manager for Nidec Machine Tool America (NMTA). He is responsible for gear machine tool sales in California, Oregon, Washington, Utah, Arizona, and British Columbia. In a first for NMTA, Mr. Hughes will also promote and help customers with the full complement of gear-cutting tools, such as hobs, shaper cutters, skiving tools, shave tools, and tool services such as sharpening and coating.

NUM Offers Tool Grinding Software to Denmark Tooling Company

TN Vaerktoejsslibning, Denmark’s second-largest precision tooling company, is deploying Numroto, the programming system for tool grinding from NUM across its entire production floor. The company cites highly successful long-term experience with the software, together with excellent technical support from NUM, as the key reasons for choosing to standardize on Numroto.

The Differential Difference!

Introducing Gleason's new Coniflex® Pro Design and Manufacturing System for producing stronger, quieter, and more reliable e-drive differential gears in high volumes, for automotive, truck, bus and off-highway transmissions. It‘s the differential difference!

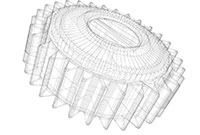

High Production Carbide Hobs

Star SU is a leading supplier of solid carbide hobs for gear tooth production. Our in-house carbide grades are available for cutting either green or hard materials and can be stripped and recoated. Application driven designs available in shell or shank configurations with multiple threads for maximum efficiencies.

Read More

Reconditioning of gear cutting tools

To ensure maximum tool lifespan and minimize costs, reconditioning tools is essential. Liebherr offers expert gear cutting services for Liebherr tools and those of other manufacturers. From hobs to skiving wheels, the sharpening and resurfacing ensure tools perform like new. Experience quality and rapid turnaround, saving your company time and resources.

Read More

2024 Fall Technical Meeting Call for Papers | Abstracts Due 19 January 2024

The 2024 Fall Technical Meeting (FTM) will be in Chicago, IL, from October 7–9. We encourage gear industry experts and professionals to submit an abstract. All abstracts must be completed and submitted in full by January 19, 2024.

Learn More