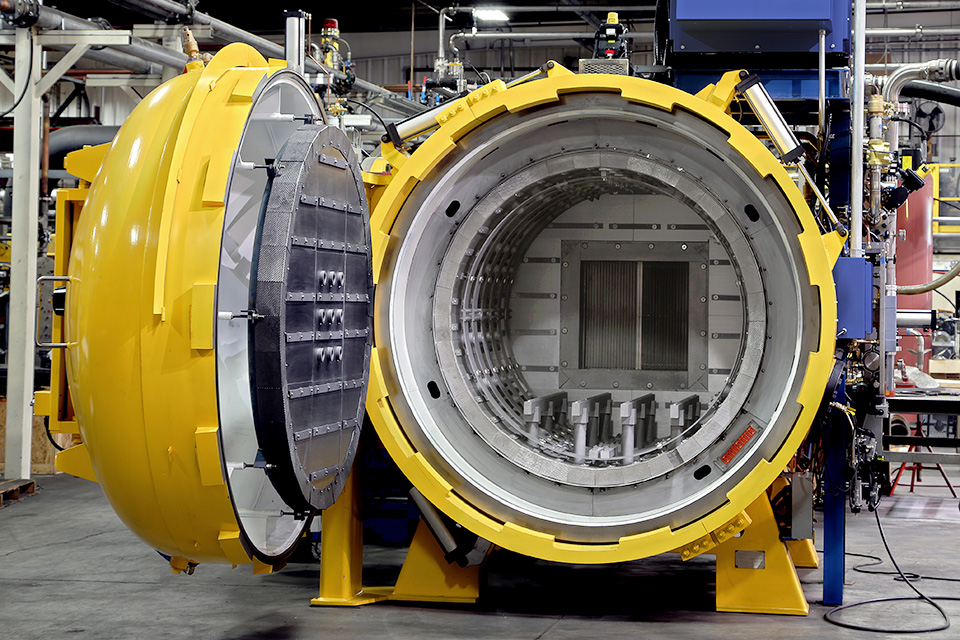

Nitrex to Deliver Seventh Vacuum Furnace to Leading Aerospace Manufacturer

A major North American aerospace manufacturer has selected Nitrex Vacuum to support its growing production needs, placing an order for a seventh vacuum furnace to expand capacity. This new vertical, large-precision vacuum furnace, built by G-M Enterprises, a Nitrex company, is engineered to meet the stringent demands of aerospace manufacturing, delivering consistent performance and reliability for critical engine components.

ECM USA’s Vincent Lelong Presented at Purdue Heat Treatment Consortium (PHTC)

ECM USA’s Vincent Lelong presented low-pressure carburizing with vacuum furnace technology at Purdue University's School of Materials Engineering undergraduate seminar. This seminar regularly features industry speakers, some of whom are members of the Purdue Heat Treating Consortium.

Insights on Atmospheres for Heat Treating Equipment

Surface Combustion is a leader in controlled atmosphere heat treating furnaces and atmosphere generators. Learn detailed information about heat treat atmospheres including, descriptions, compositions, generation methods, and applications. This is a fantastic resource for heat treat operators, metallurgists, and maintenance technicians. Contact Surface Combustion to discuss your specific requirement.

4D Quench Predicts & Controls Distortion

SECO/VACUUM's UniCase Master® single-piece flow vacuum furnace virtually eliminates all post-heat treatment costs associated with distortion. It takes parts from your machining center, heat treats them under vacuum, quenches from all sides using multiple high-pressure gas jets as the part rotates (the 4th dimension), then automatically delivers them to the next manufacturing process.

Learn More

Assure Quality Repeatability with Vacuum Furnace Technology

If you do CARBURIZING, BRAZING, FNC, HARDENING, SINTERING, ANNEALING…then you need an ECM vacuum furnace system to transform your heat treat operation. Our innovative vacuum technology allows for higher temperature treatments to maximize production efficiency, reduce production costs, ensure quality repeatability, optimize energy consumption & improve employee safety.

Read More

Unlock Your Team’s Potential with the AGS Learning Center!

Discover cutting-edge online training for your workforce on Gear Process Engineering, Preventing Handling Damage, and more. For your leaders, don’t miss our Tech Talk Series featuring industry experts sharing their insights on the latest technologies and methods! Elevate the skills of your team and drive success today!

Read More

High Pressure Quench Vacuum Carburizing Furnaces

Get fast, forceful gas cooling with Solar Manufacturing’s IQ series of vacuum carburizing furnaces. It’s high performance internal quench system with direct-exit, sliding radiation baffles is the least restricted gas flow path on the market for superior hardening at quench pressures up to 20 bar. Contact us to learn more about our vacuum furnace ingenuity at 267.384.5040.

Read More

Join us for Analytical Gear Chart Interpretation

AGMA is hosting our Analytical Gear Chart Interpretation on January 29, 2025 online! For more information such as dates and times and registration deadline, click on the link below.

Register Now

Paramax 9000 Secures Multiple Awards at VA Manufacturing Gala

This year’s Virginia Manufacturing Gala, hosted by the Virginia Manufacturers Association (VMA) at the prestigious Virginia Museum of History and Culture, served as a showcase for the best in Virginia’s manufacturing industry. At this prominent event, Sumitomo Drive Technologies stood out significantly, earning Bronze in the Virginia Manufacturing Cup and capturing 1st Place in the Industrial and Commercial Machinery category with its Paramax 9000 reducer.

Read More