A Sneak Peek at Quality Control at Atlantic Bearing Services (ABS)

This recent day in the life feature shows the ABS quality team in action to ensure manufacturing precision. Antonio Martin Hernandez, Marco Partidas, Dayan Leng Armenteros, and Laura Vazquez diligently worked on various components that required special attention. They are focused on inner rings (IRs) for cylindrical roller bearings, which play a crucial role in reducing friction and supporting radial loads. Additionally, they handle bevel gears, essential components in gearboxes that change the direction of torque transmission across various industrial applications.

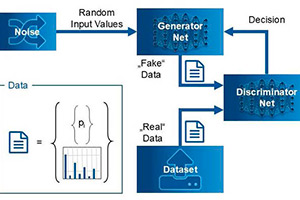

Virtual End-of-Line Test

Tooth contact analysis is an integral part of the gear design process. With the help of these simulation tools, it is possible to calculate the excitation caused by a tooth contact (Ref. 1). Usually, the load-free transmission error or the total transmission error under load is used for this purpose.

Industrial Automation Integrity

Truth be told, there are few components as versatile as the gearmotor. We find them in AGVs, AMRs, and robotics. They can also be found in automation equipment, industrial drive solutions and material handling applications. Four key trends involving gearmotors today include the simplification in design and installation, quiet and energy efficient performance, predictive maintenance and condition monitoring—and lastly—the ability to perform at the highest levels in hazardous and demanding applications.

Changing Entertainment Experiences with Electro-Mechanical Screw Jacks

There has been a significant shift in the Entertainment Industry to move away from manual and hydraulic operated systems to electro-mechanical screw jacks. Key reasons are safety, cleanliness, sound and reliability. Providing the ultimate entertainment experience dates back centuries, where lifts and trap doors were all part of making people, animals and staging, all of a sudden appear. This industry still uses these techniques today, but how they operate has changed dramatically.

Trusted Gearing Solutions Since 1925 for Superior Performance

Since 1925, Cone Drive has delivered trusted double-enveloping worm gearing, renowned for high torque and superior performance. Our innovative designs ensure increased load capacity, reduced contact stress, and enhanced shock capacity. We specialize in worm, harmonic, cycloidal, and slewing solutions, providing reliable motion control for your most demanding applications.

Read More

Our High Torque Gears Fill a Key Design Gap.

For over six decades, we’ve helped top engineers tackle tough gearing problems. Application industries include: Robotics, Aerospace, Defense, Transportation and Medical.

Learn how our gearing systems can be leveraged in your sector. Contact our engineers today at 320-762-7133 for more information.

Download Case Studies Here>

NES split-ring bearings offer greater thrust capacity

The NES split-ring bearing is a single-row, angular contact bearing which supports axial loads in both directions, thereby reducing overall size and weight compared to traditional duplex sets. Pair an NES split-ring and standard angular contact ball bearing for double the load capacity in the primary load direction. Contact NES to learn more.

Read More

NEW Power Plant Repair Case Study

The issue started with excessive gearbox vibrations. The power plant contacted PHILADELPHIA GEAR®, who identified a broken gear and misaligned housing bores. But the plant couldn’t wait to procure new housing. Read the case study to see how PHILADELPHIA GEAR worked creatively, restoring the unit in just two weeks.

Read More

Customized: The Key to Optimized Performance

From everyday devices to life-saving surgical robots, SDP/SI designs and manufactures high-precision gears, mechanical and electromechanical components, and tailored subassemblies that power them. Whether you need a standard part or a bespoke solution, our team of engineers and manufacturing experts is ready to assist. Discover all the options.

Read More

Join us for Loaded Tooth Contact Analysis

AGMA is hosting our Loaded Tooth Contact Analysis on January 30, 2025 online! For more information such as dates and times and registration deadline, click on the link below.

Register Now