Liebherr Supply Slewing Bearing for Europe’s Largest Lifting Swing Bridge

Liebherr’s components product segment supplies the heart of the rotating pillar for the bridge Friesenbrücke, which is being erected for Deutsche Bahn in Weener. It comprises a 5-meter, 12.5-ton combined roller and ball bearing along with eight matching pinions.

5 Ways to Save Money Through Ultrasonic Analysis

When facilities are designed and built to meet the standards of the day, the plant is as efficient as it will ever be on day one. However, as the plant ages and production demands increase, aging equipment becomes strained leading to inefficiencies and escalating costs.

To Pick the Right Drive, Ask the Right Questions

Selecting a drive, whether for a new application or to replace an existing one, doesn’t have to be a traumatic experience. The key to success lies in asking a logical sequence of thoughtful questions.

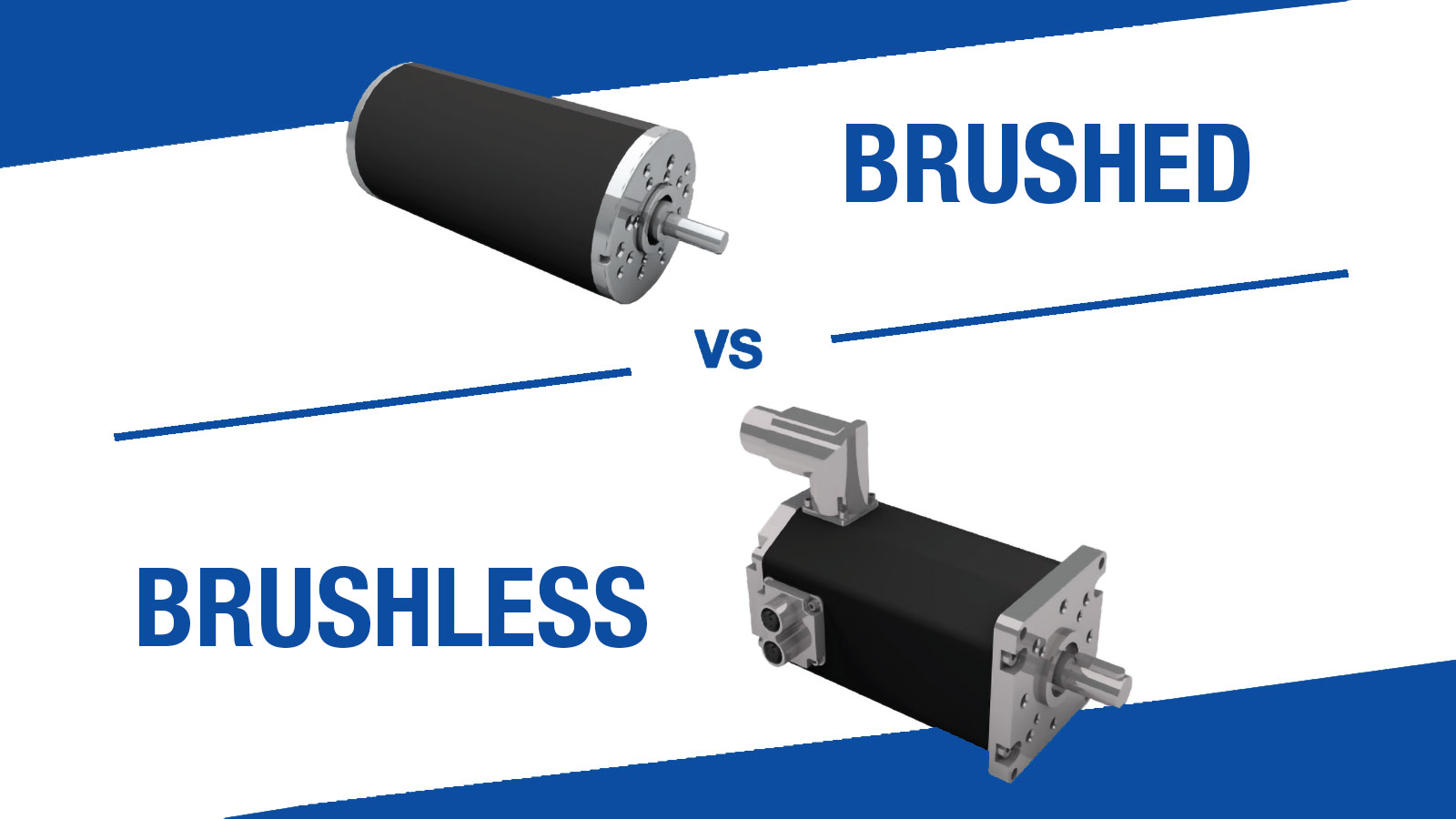

Brushed vs. Brushless DC Motors

Which is right for your application? This whitepaper from Dunkermotoren presents an in-depth comparison of brushed and brushless motor technologies, exploring their construction, operation, efficiency, performance characteristics, and real-world applications. By analyzing key parameters such as power efficiency, maintenance requirements, and cost-effectiveness, engineers and designers can make informed decisions when selecting the appropriate motor technology for their specific needs.

Brakes are designed for requirements of robot arms

BXR Brakes from Miki Pulley are two-thirds the thickness of older models. No projections to interfere. Dedicated for holding and emergency braking. Space-saving mountings and lighter weight lowers inertia without degrading response of servo motors.

Learn More

NEW Power Plant Repair Case Study

The issue started with excessive gearbox vibrations. The power plant contacted PHILADELPHIA GEAR®, who identified a broken gear and misaligned housing bores. But the plant couldn’t wait to procure new housing. Read the case study to see how PHILADELPHIA GEAR worked creatively, restoring the unit in just two weeks.

Read More

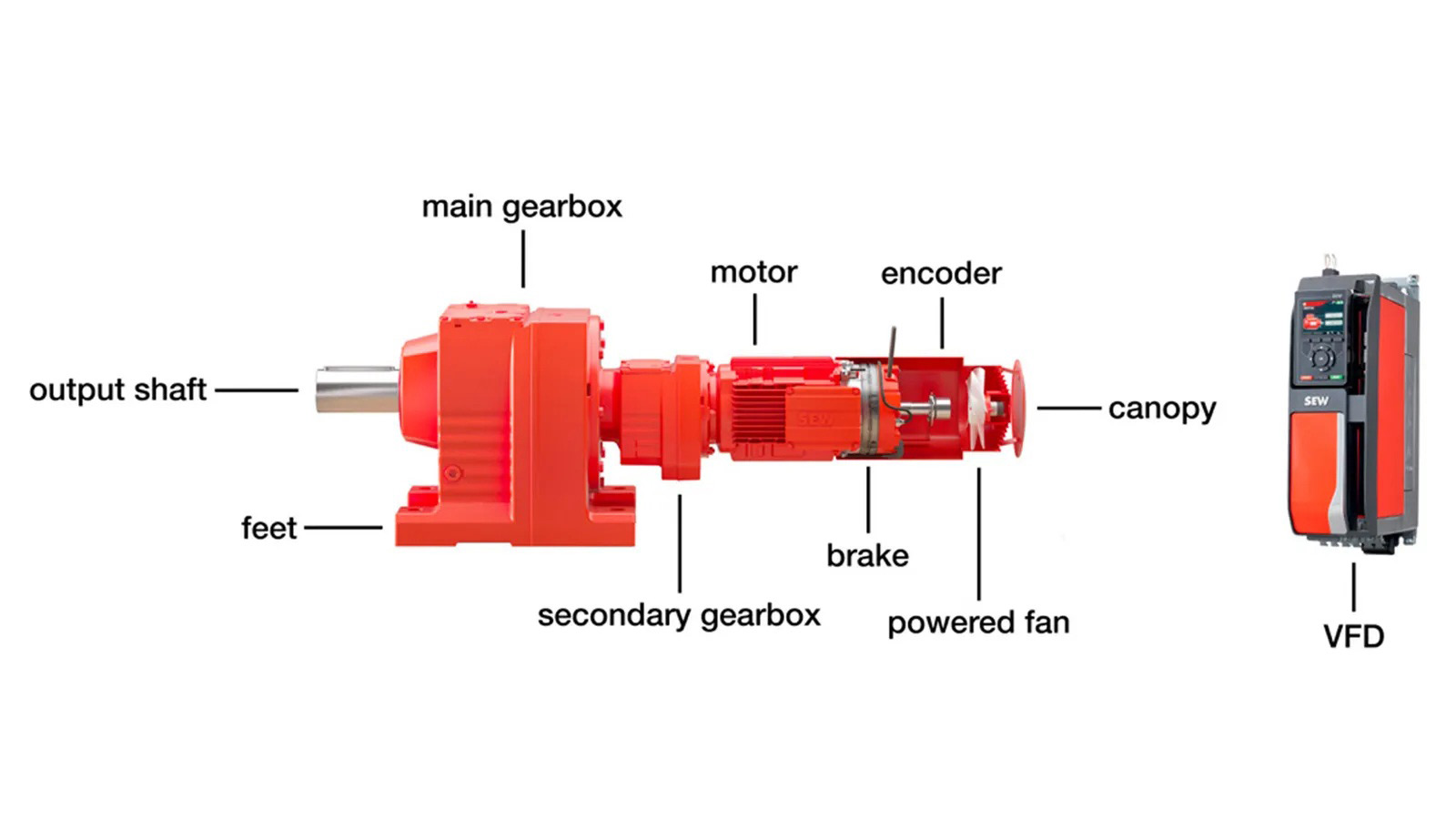

NORD Complete Drive Solutions Are Powerful, Reliable, and Efficient.

NORD DRIVESYSTEMS designs and manufactures modular gear reducers, electric motors, and variable frequency drives (VFDs) that are engineered for adaptability. With more than 20,000,000 standard gear motor combinations and a strong worldwide supply network, NORD’s innovative solutions ship quickly and can be precisely configured to power highly specialized applications.

Read More

New from SEW-EURODRIVE: WES Series Stainless Steel Drives

The WES Series stainless steel gear unit sets a new standard—cool-running, compact, and rated for washdown environments. Unlike other worm gears, it minimizes heat, maximizes efficiency, and eliminates failure points, ensuring reliable, hygienic performance for food, beverage, and pharma applications.

Read More

High Performance Spiral Bevel Gearboxes

With more models, sizes, and ratios, DieQua's spiral bevel gearboxes offer precision, performance and durability far above standard products. They're ideal for applications requiring high speed, precise motion control, high torque, or heavy shocks. Several configurations, options, and customized solutions provide unmatched design versatility.

Read More

Join us for Basic Training for Gear Manufacturing

AGMA is hosting our Basic Training for Gear Manufacturing on April 7-11, 2025 in Chicago, IL at the AGMA National Training Center! For more information such as dates and times and registration deadline, click on the link below.

Register Now