|

Catch up on the latest news and updates.

|

|

|

| LIFT Opens Advanced Metallic Production and Processing (AMPP) Center in Detroit |

LIFT, the Department of Defense-supported national advanced materials manufacturing innovation institute, has officially opened its state-of-the-art Advanced Metallic Production and Processing (AMPP) Center in Detroit’s historic Corktown district. This facility will play a critical role in strengthening the U.S. industrial base by accelerating the design, development, and deployment of novel metallic materials, filling a key gap in the nation’s defense manufacturing base.

|

|

| Humanoid Component Advancements |

Schaeffler continues to advance key technologies shaping the future of mobility and motion. One area of interest—humanoid robots—is where Schaeffler is developing advanced component and system capabilities for the next generation of robotics. PTE recently had the opportunity to discuss these technologies with Al Makke, engineering director, humanoid robotics, North America, at Schaeffler Group USA.

|

|

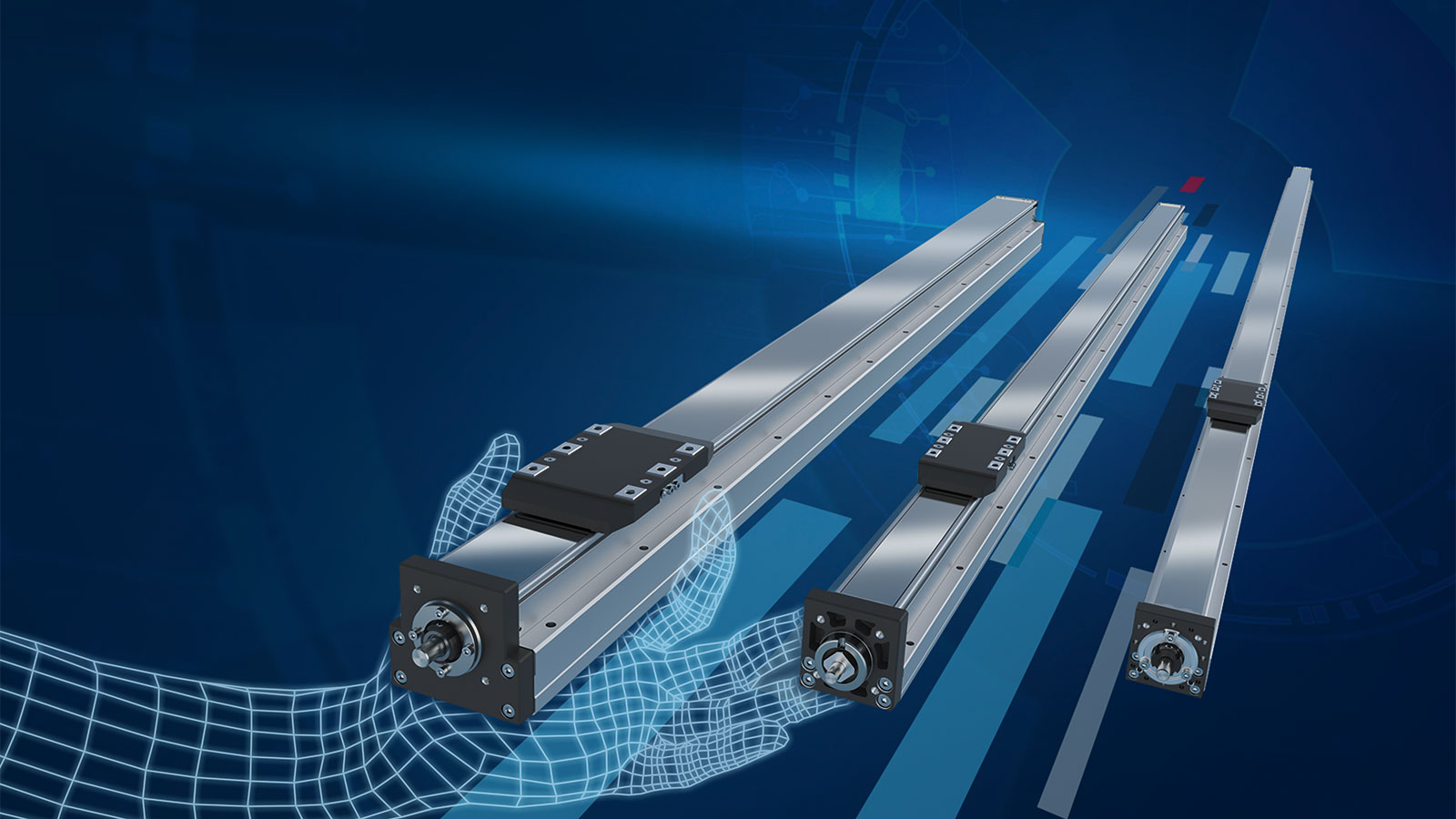

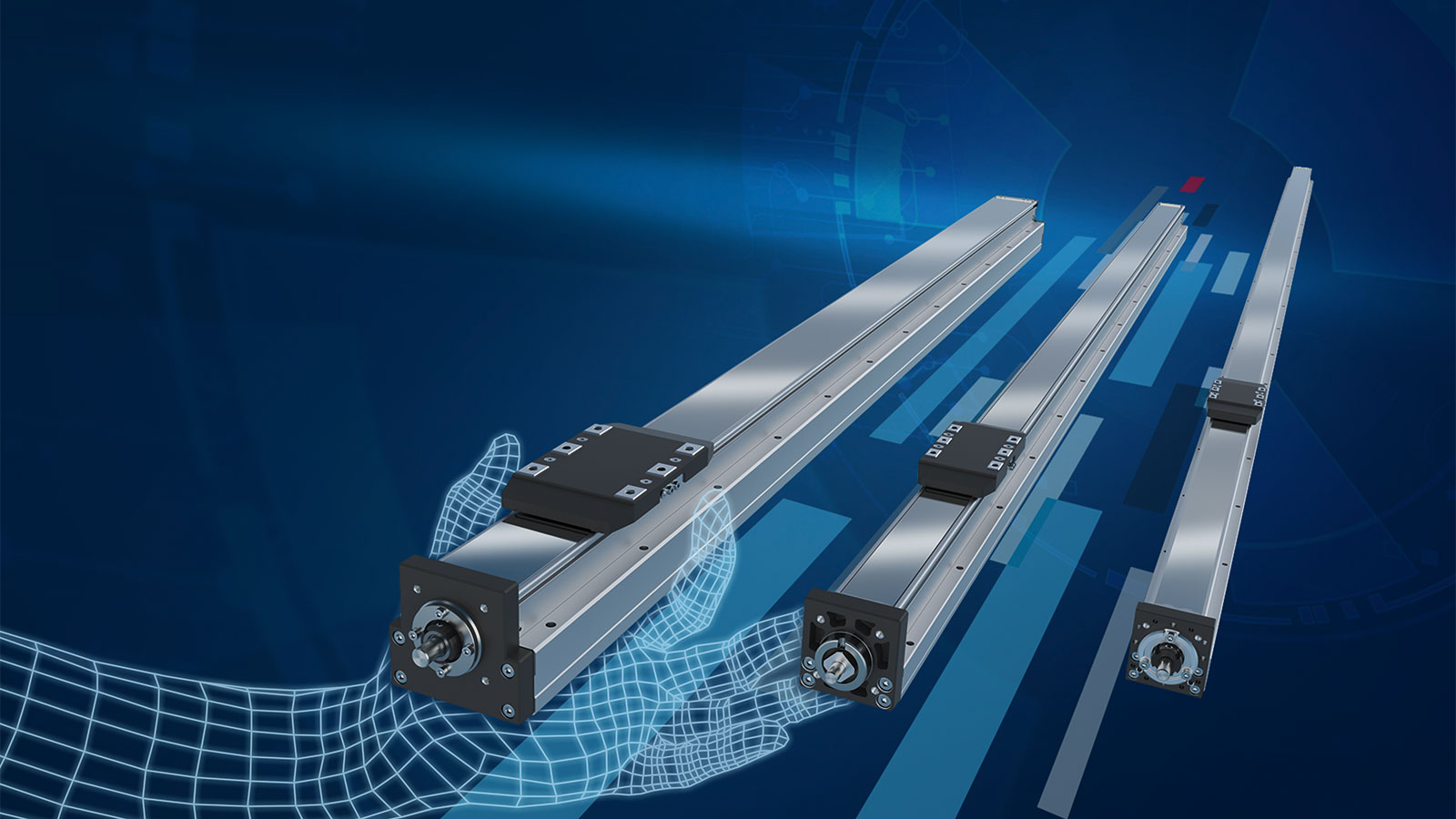

| Selecting the Right Linear Axis for Your Automation System: A Beginner’s Guide |

Foundational to factory footprints across a breadth of industries and applications, linear motion systems and the axes they operate on remain critical components that OEMs and end-users rely on daily. As diverse as their use cases, linear axes are not a one-size-fits-all solution and, as such, need to be configured and leveraged properly to ensure optimal performance.

|

| [Sponsored Content] |

|

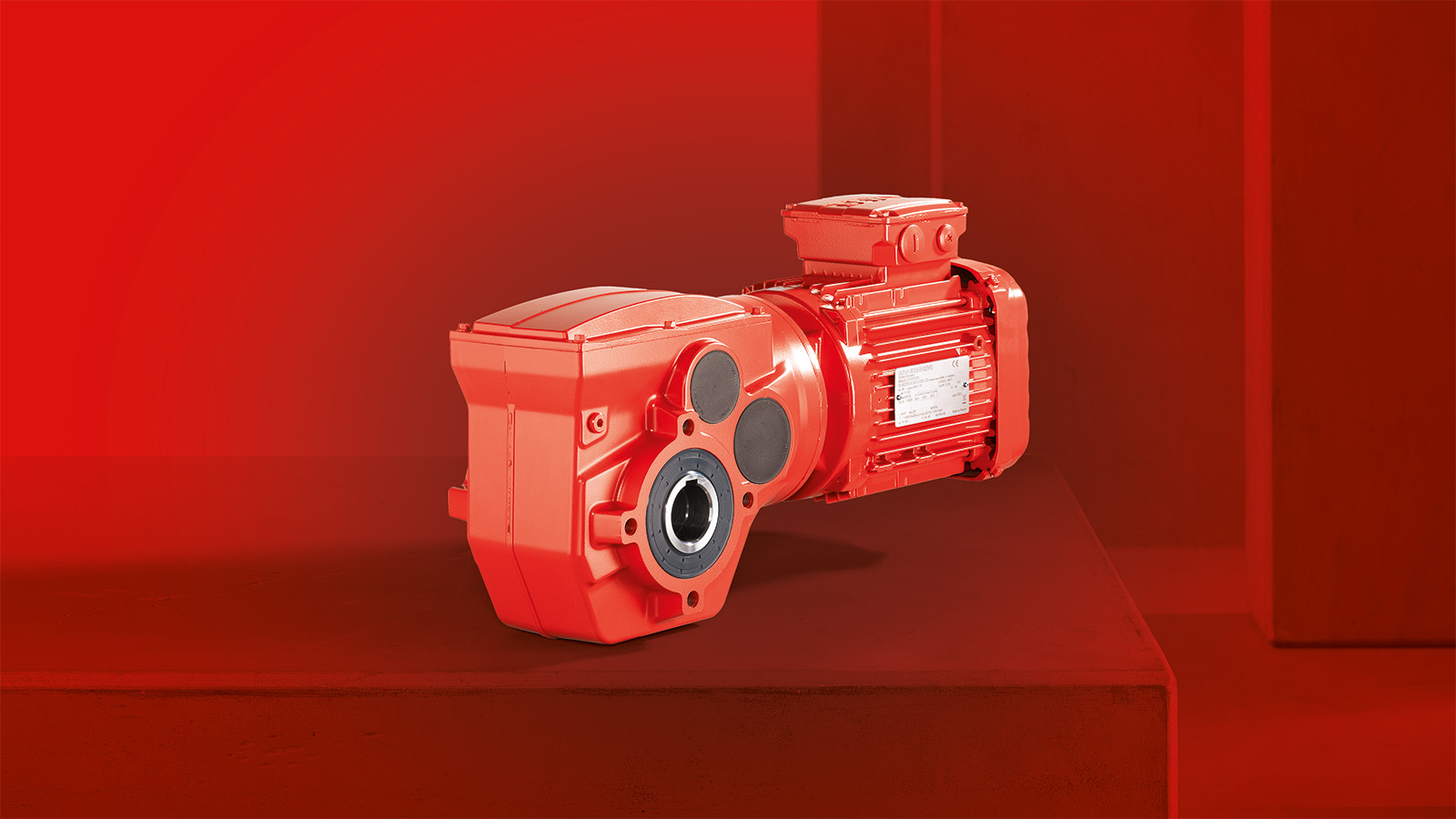

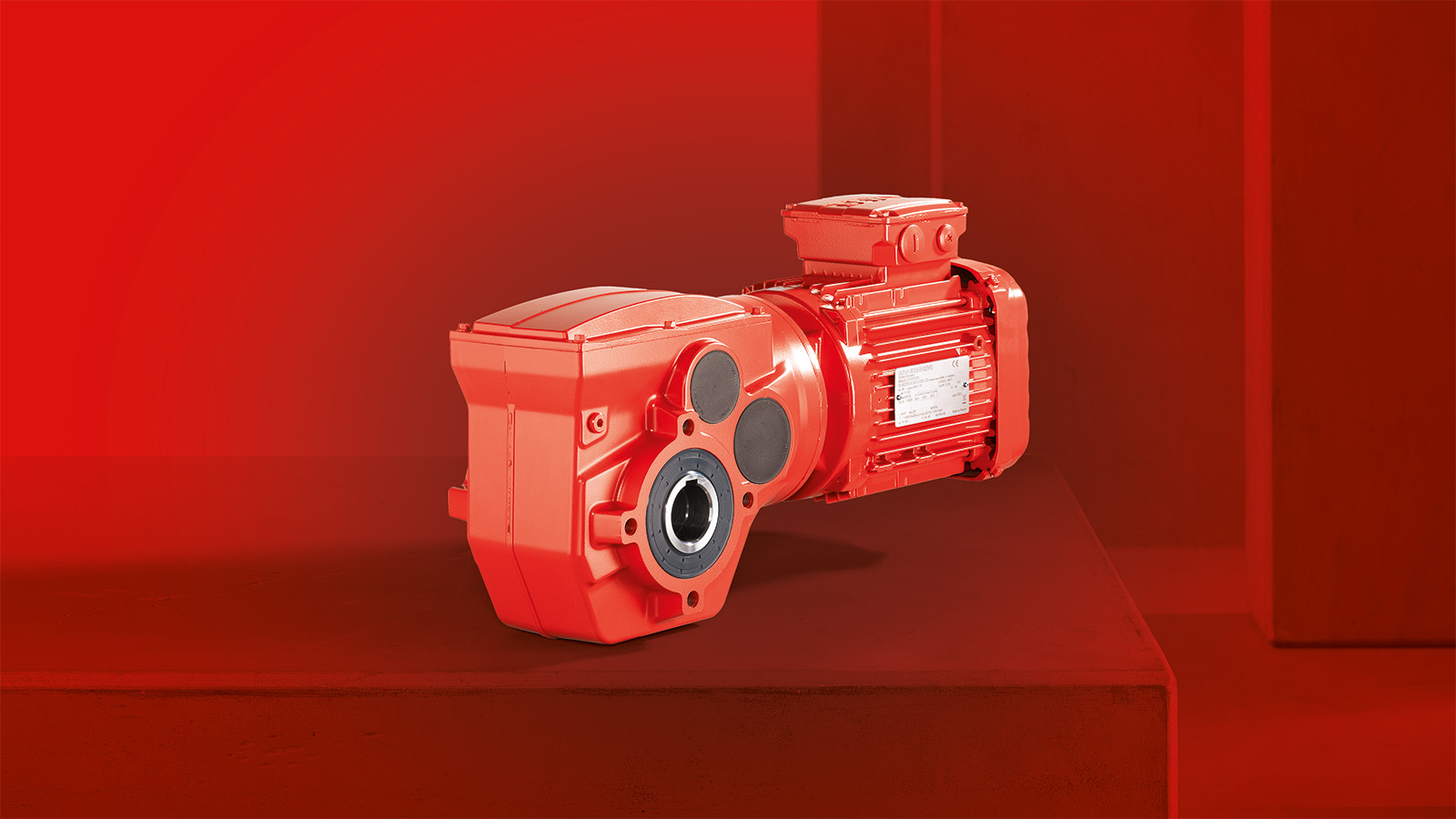

| Compact Power, High Gear Ratios |

Looking to reduce speed and increase torque—without the size and complexity of a compound gear unit? Discover how the W..9HG SPIROPLAN® delivers gear ratios over 2000 and torque up to 600 Nm in a compact, quiet, and efficient design.

|

|

| [Advertising] |

|

|

|

| Industrial Worm Speed Reducers |

Our standard industrial worm speed reducers provide improved performance, high reliability and easy maintenance. Offered in 7 sizes with center distances from 28 - 110mm. Featuring a flexible coupling input, all aluminum housings, and NEMA, IEC, or servo motor adapters.

|

|

|

| Trouble Sourcing Steel Disc Couplings? |

R+W has invested significantly in its ability to deliver standard length single and dual flex steel disc couplings with an average lead time of less than two weeks. Zero backlash, precision machined, and robust, with custom options also available.

|

|

|

| Learn the 4 most common servo coupling applications |

Servo coupling selection usually starts with a decision between torsionally stiff couplings and vibration damping couplings. Almost all applications can be categorized into one of four key types. Learn the rules of thumb for each along with some easy ways to calculate positioning accuracy and error attributable to the coupling.

|

|

|

|

| IronHorse® Worm Gearboxes from AutomationDirect |

New models of aluminum gearboxes with IEC input flange types B5 and B14 to fit IEC motors in several frame sizes. Hollow shaft outputs and more. Lower cost, lower weight alternative to steel and cast-iron models; prices start at $118.00.

|

|

|

| Which Type of Motor is Best for YOUR Application? |

Every application has unique needs in terms of efficiency, torque, speed control and more. This whitepaper from Dunkermotoren covers applications including appliances, power tools, building automation, agriculture, aerospace, automation and more. Learn the pros and cons of both traditional brushed motors and brushless DC.

|

|

|

| Discover What SDP/SI Can Do for You |

SDP/SI designs, engineers, and manufactures precision gears and mechanical components in-house. Our experienced team can create custom solutions, whether it’s a single gear or a complete drive system. We also offer assembly of mechanical and electromechanical subassemblies. Contact us today about your needs!

|

|

|

|