[please visit our sponsor]

Continental Takes for the Sky for Inspection System

Continental offers the CONTI ConveyorInspect drone-based inspection system to allow operators to easily know the condition of their belts and idlers, quickly locate the exact position of failing idlers, and track changes in rotating components over time. With this real-time reporting, operators can better estimate their system’s component life and plan their maintenance. This helps prevent costly damage of conveyor system components and minimizes downtime.

Sulzer Examines Cost-Effective Solutions for Pumps and Mixers

Pumping systems are responsible for over 20 percent of the world’s electrical energy demand, and in some industrial plant operations, they can account for up to 90 percent of energy usage. Improving the energy efficiency of pumping and mixing systems is crucial in reducing production costs and supporting a more sustainable future. Several options can be available and with energy prices reaching new heights, the return on investment is rapidly reducing.

Industrial Worm Speed Reducers

Our standard industrial worm speed reducers provide improved performance, high reliability and easy maintenance. Offered in 7 sizes with center distances from 28 - 110mm. Featuring a flexible coupling input, all aluminum housings, and NEMA, IEC, or servo motor adapters.

Read More

Keep equipment running with Philadelphia Gear

When communities count on uninterrupted power, Philadelphia Gear delivers the mission-critical gear drive support to keep entire cities moving. Access end-to-end services—including OEM parts and aftermarket repair—to ensure your equipment runs reliably for decades to come.

Read More

Linear Motion Components for Precision Applications

QBC is a trusted supplier of the world’s largest bearing and linear motion component manufacturers. Designed to work together Thomson linear components provide trouble free installation, reliability and exceptional performance. Shop QBC!

Shop Now!

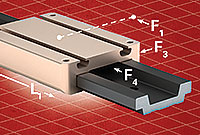

Understanding the Binding Ratio

Since PBC Linear introduced the 2:1 Ratio principle to the marketplace, it has been quickly adapted by most self-lubricating, linear plain bearing manufacturers as one of the guiding principles regarding their use. Within our white paper, we explain the importance of the 2:1 ratio as well as its practical complications, limitations and troubleshooting.

Download White Paper

Protect Uptime with reliable Grove Gear® IRONMAN® gear reducers

When durability is critical, look to Grove Gear© IRONMAN©, the heavy-duty gear reducer that handles the environmental assaults, shock loading, frequent reversing and continuous duty cycles typical in many industrial applications. See more drive features that protect uptime and keep operations running smoothly here: RegalRexnord.com/IRONMAN

Read More

High Performance in Rotating Machinery: NSKHPS

For reliability in motors, pumps and fans, NSKHPS Cylindrical Roller Bearings deliver high loads and high speeds with low heat generation. An optimized design with superior roller guidance results in low wear and long operating life.

Read More