Oil Shear Crane Brake Solves Maintenance Headache

Working three shifts around the clock throughout the week doesn’t leave time in the schedule for production downtime in Southern Aluminum Finishing’s anodizing line in Atlanta, Georgia. However, they found themselves frequently grinding to a halt as their crane brakes demanded continual maintenance.

A Smarter Seal for the Long Haul

Isomag magnetic bearing isolators use superior face seal technology to protect the bearings on thousands of centrifugal machinery including but not limited to: pumps, gearboxes, electric motors, steam turbines, and blowers. The lapped flat faces create a positive liquid tight seal preventing lubricant leakage and the ingress of contaminants.

Expect Increased Efficiency with Hypoid Gearing Instead of Worm Gearing

Worm gears are the most common. An alternative is the hypoid gear. Hypoid gears may look similar to worm gears but due to the materials used for construction and the difference in how hypoid gears interact, they transmit torque differently. Hypoid gears can show an overall cost and efficiency advantage.

Cost Effective High Precision Linear & Rotary Axes

Andantex, USA, a member of the Redex-Group, offers modular system building blocks consisting of Hardened & Ground Racks, High Quality Planetary Reducers including Output pinions, Ring Gears and Automatic lubrication systems to build linear axes of any length and move weights from 100 to 200,000 Lbs.

Download White Paper

Motor Brakes That Never Need Adjustment – Ever!

MagnaShear Oil Shear Motor Brakes require very little maintenance other than an occasional fluid change, and they never need adjustment over years of trouble free service. This high reliability not only reduces cost but is a major safety improvement, especially on overhead cranes.

Learn More

Hollow Socket, No Coupling Shaft Design

NORD’s innovative single-stage inline speed reducers take standardization to a new level. These alignment-free gear units make installation easy with no need for shimming and offer a long list of standard features, including a one-piece UNICASE housing, Autovent pressure regulation, and high-strength, high-precision, carburized gearing and high-capacity bearings.

Learn more

Maximum bearing uptime for wind power drivetrains – NSK AWS-TF Bearings

The AWS-TF Series of bearings was designed expressly for wind turbine gearbox applications, achieving up to 7 times the life of standard bearings in hydrogen-charged environments. That means dramatically extended service intervals, increased efficiency and lower operating cost.

Visit NSKAmericas.com/Wind

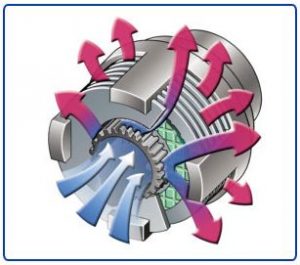

Inline Helical Gearmotors & Speed Reducers

Our inline helical gear reducers are offered in 14 sizes, with torque capacities up to 14,000 Nm, input power capacities from fractional to 75 HP, gear ratios from 1:1 to 13,500:1. Multiple input options include integral gear motors, inch or metric shafts, NEMA, IEC, and servo motor adapters.

Read More

Learn more about AGMA’s Motion + Power Technology Expo

Mark your calendar for in-person education, networking and product demonstrations at AGMA’s Motion + Power Technology Expo, formerly Gear Expo, September 14-16, 2021, in St. Louis, Missouri. At MPT Expo, you’ll see the full range of power transmission solutions, utilizing mechanical power transmission, pneumatics, hydraulics, electric motors, and drives.

Learn More