Everything You Ever Wanted to Know about Couplings

Dive into our archive for detailed information about couplings, from technical articles to case studies to the latest product news and information for your applications.

Overview and Application Guide for Screw Jack Systems

DieQua offers complete screw jack system design assistance, taking the guess work out of product selection. Our years of application experience assures that all elements of the design process are considered. We also offer full assembly drawings, which provides time-saving value, and guarantees that the correct system components are integrated.

High-speed couplings handle 24,000 RPM with high torque

Miki Pulley introduces SFM coupling line for direct sale to OEM's in North America. SFM couplings are for high-speed power transmission applications up to 24,000 rpm where high torque and precision alignment is critical. 10 sizes available. Speed range up to 24,000 rpm. Torque rating 60 N•m to 600 N•8 depending on model size.

https://www.mikipulley-us.com

Dodge® Passport - Smarter. Faster. Empowered.

Dodge® Passport is the new, easy-to-use online selection program for product and application-based solutions using Dodge mechanical power transmission products. Passport improves productivity and ensures cost-effective and reliable selections through real-time pricing and availability, performance-matched components, and quote-to-order capabilities. With enhanced technical capabilities, Passport also allows you to customize selections and receive detailed technical data.

Read More

Complimentary White Paper on the Basics of Bellows Couplings

Over the past few years the metal bellows has been employed in an increasing number of critical machine drive applications. Its unique characteristics can help optimize positioning accuracy, balance, service life, and system stability. In this paper we explore where they came from, why they're used, and other best practices...

Read More

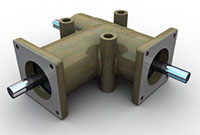

Anglgear right angle drive

Our Anglgear™ line, made in the USA, consists of 14 different models available from stock in both an Inch and Metric series; 1:1 or 2:1 ratios, 2 or 3 shafts, and 2 flanged or 3 flanged units. We also modify our standard units to meet our customer’s design specifications.

Read More

Safely Remove Stuck Drive Components

The new QBC/BETEX iDuctor is the ideal tool for safe and fast removal of metal parts such as nuts, bolts and bearings. The hand-held iDuctor allows access to hard-to-reach places, heating and loosening stuck parts in seconds. Specify the iDuctor, comes complete with accessories and carrying case. Download product specifications.

Read More

Kollmorgen Releases Latest Version of Motioneering

Kollmorgen has introduced the next generation of Motioneering, the company’s innovative servo sizing tool. Motineering was introduced more than 20 years ago – the first tool of its kind – to help mechanical design engineers find the ideal motion products to build into their machines. It streamlines and simplifies the design process by incorporating 100+ years of Kollmorgen expertise about which motion solutions work best for specific applications such as factory automation, robotics, material forming, and many others.

Read More