A Look at Servo Technology for Power Transmission Systems

This article looks at the latest news on servo motors, drives and motors. How do we differentiate between the definitions? What can design engineers find between a stepper and a servo motor? Also, a quick update this summer on the benefits of closed-loop motor control.

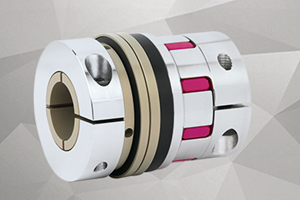

QUICK REACTING AND READILY AVAILABLE TORQUE LIMITERS

Proper torque overload protection is often omitted from machine design over concerns about size, inertia, and performance – not to mention long lead times. The SLE addresses all of this with a compact low inertia design that runs backlash free and disengages within milliseconds of an overload. It’s also readily available.

Get More Uptime In No Time.

Whatever the job, there’s a Continental Belt ready to handle it. With state-of-the-art designs, they’re effective solutions to maximize production, reduce maintenance costs, and keep your operations moving forward.

Read More

NORD MAXXDRIVE XT Industrial Gear Units: Built for Extreme Environments

MAXXDRIVE XT IGUs provide up to 663,800 lb-in of torque, ratios of 6.3:1 - 22.4:1, and 30 - 2,825 HP. All bearings and sealing surfaces are machined in a single process for quiet operation and long service life. XT units have a high thermal limit and can be supplied ready-to-install with couplings, brakes, monitoring, and more.

Learn More >>

STAGES BUILT IN THE USA

HIWIN can design, engineer, manufacture and test the best solution for your single- or multi-axis stages, using our substantial in-house machining and fully-stocked inventory, plus any special modifications needed.

Download Now

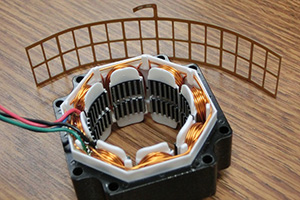

Servo Motor Systems, Assemblies, and Application Expertise

SDP/SI’s compact DC Servo Motors are ideal where rapid acceleration and deceleration are required. The motors are available in five frame sizes and include thermal protection, incremental encoder, and brake options. Let us configure the best system to satisfy your performance and reliability requirements.

Request a quote online!

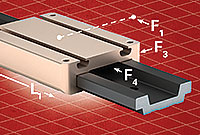

Understanding the Binding Ratio

Since PBC Linear introduced the 2:1 Ratio principle to the marketplace, it has been quickly adapted by most self-lubricating, linear plain bearing manufacturers as one of the guiding principles regarding their use. Within our white paper, we explain the importance of the 2:1 ratio as well as its practical complications, limitations and troubleshooting.

Download White Paper

Performance Plus Savings With Powder Metal Gears

Powder Metal Technology allows a more cost-effective production of gears. Plus, it eliminates the waste in resources and energy that more costly casting and machining methods require. We can help with your spur, helical, bevel, ring, miter, compound and worm drive gears.

Read More