Reliable, User-Friendly Planetary Gear Unit Design

Stöber Antriebstechnik GmbH + Co. KG rely on the FVA-Workbench for dimensioning and verification of their drives. The calculation and simulation software allows Stöber engineers to develop their innovative gear unit solutions more quickly and efficiently. The result: higher quality products.

White Paper: Size Your Gearbox Correctly

When your equipment calls for a right angle gearbox, proper sizing makes a difference. However, simply matching a gearbox to the same sized drive motor is not the best approach. A wide range of application factors must be considered, or you will face increased maintenance, worn teeth and reduced mean time between failure.

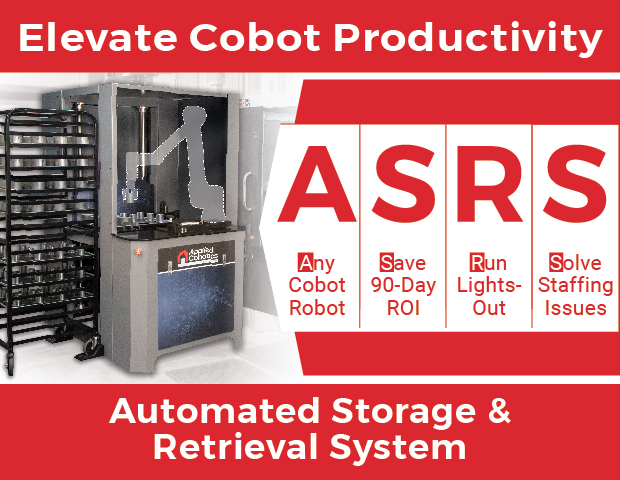

Elevate Your Cobot/Robot Productivty

PBC Linear has implemented the ASRS and cobots to great effect on the CNC mills and lathes that produce their signature bearings. With roughly 80 CNC machines in their shop and 15 cobot stations in operation, the ASRS has boosted cobot production up to 1600%, and created a more flexible manufacturing model while elevating profits

NORD MAXXDRIVE XD Industrial Gear Units: Designed for Lift and Hoist Applications

MAXXDRIVE XD industrial gear units have extended center distances to allow maximum space for the U-shape arrangement of motors and rope drums on the same side of the gearbox. This new series features five case sizes, 3-stage and 4-stage reductions, and torque output up to 991,300 lb-in. MAXXDRIVE XD units also deliver stable nominal torque ratings throughout the total ratio range, reducing drive weight up to 60%.

Learn More >>

Over 60 years, engineers have relied on Spiroid® gearing.

From robotics to aerospace, our gears provide the most compact, highest torque and customizable solutions on the planet. It’s the perfect balance of torque, efficiency and ratio flexibility.

Find out if Spiroid Gearing is the best fit for your application. Consult our engineers directly today at 320-762-7133.

VISIT OUR CASE STUDY LIBRARY

Brakes are designed for requirements of robot arms

BXR Brakes from Miki Pulley are two-thirds the thickness of older models. No projections to interfere. Dedicated for holding and emergency braking. Space-saving mountings and lighter weight lowers inertia without degrading response of servo motors.

Learn More

Standard Industrial Worm Speed Reducers

Our standard industrial worm speed reducers provide improved performance, high reliability and easy maintenance. Offered in 7 sizes with center distances from 28 - 110mm. Featuring a flexible coupling input, all aluminum housings, and NEMA, IEC, or servo motor adapters.

Read More

The Reliable Bevel Gear Supplier from Taiwan

With more than 30 years’ experience to supply bevel gears from Taiwan to the world, we are one of the leading bevel gear manufacturer in Asia.

We have qualified by IATF 16949, if you are looking for Automotive, Gear Reducer, and Machine center Bevel Gears, please feel free to contact us.

Read More

Industry’s most Comprehensive Selection of Metric Gears

QTC METRIC GEARS stock spur gears, helical gears, miter & bevel gears, worm and worm wheels, internal gears, and gear racks are available. Product specifications, 3D CAD models, price and availability are online. Shop QTC METRIC GEARS 24/7. Call us for customization.

Request a quote online.

Complex Structural Components For Less

Precision component parts of the highest quality can be produced at a lower cost using powder metallurgy (PM). Let Symmco’s engineers help you to save money.

Read More

Siemens Digital and Sustamize Collaborate on Carbon Emissions Data

To provide access to the most up to date CO2e emission data for materials and energies, Siemens Digital Industries Software recently announced its collaboration with sustamize GmbH, a leading ClimateTech company providing professional technology, data and software solutions enabling companies to measure, optimize and manage CO2 emissions.

Read More

Join us for our Gear Materials course!

Our Gear Materials course taught by Ray Drago and Dale Weires, October 18-20 at AGMA’s National Training Center in Chicago. Learn about designing an optimum gear, the importance of coordinated efforts between all engineers, and gear-related problems.

Register Today!