Considerations for Choosing the Correct Rolling Element Bearing Characteristics

Daily experience in application engineering has proven that the selection of the correct bearing type can be successfully achieved by customers based on the documentation and tools provided by the bearing manufacturer and using comparable applications as a guideline.

Eliminate Metal Contaminants with the CORE™ System

Say goodbye to ferrous metal lubricant contamination. Philadelphia Gear’s compact CORE™ (Continuous Oil Rescue Equipment) system extends lubricant life, reduces the need for spare filters, operates with no pressure drop, and enables upstream filter installation. Contact Philadelphia Gear to start reducing equipment failure rates today.

Read More

New Digital controller available from Andantex USA Inc.

The DG-Block is the new benchmark in closed loop digital controller for any industry using equipment managing a large number of wires, cables, fibers or even narrow webs, in a very compact controller.

A true turnkey solution relying on an intuitive programming system based on an exclusive computer software (DG-BlockSoft).

Read More

Strategies for Assessing and Optimizing Bearing Running Noise

The noise behavior of rolling-element bearings is an important indicator of quality - but understanding what is causing the noise often involves complex simulations. The Schaeffler Noise Index (SGI) is a new, ready-to-use rating tool designed to help users select the right bearing for the right application.

Read the White Paper

Zero Room for Gear Drive Failure Aboard This Ship

For more than 125 years Philadelphia Gear has delivered mission-critical performance and reliable support for the U.S. Navy, even 1000’s of miles offshore. Click to see what “Philadelphia Gear dependability” looks like.

Read More

ARMOR BEARING TECHNOLOGY now available on AXPB RBTECH bearings. By RBI Bearing.

Reduce downtime, operation costs and

significantly extend bearing life with

ARMOR Bearing Technology.

- ARMOR Nano Technology

- ARMOR Permanent Lubrication

- ARMOR Coated Protection

Read More

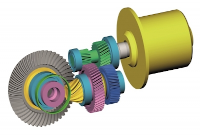

KISSsoft Examines E-Mobility Applications

The increasing number of electric vehicles is already having an impact on the design of transmissions. Although the number of gears in e-mobility applications is typically lower than in conventional passenger cars (see kinematics example), the requirements for low-noise and low-vibration transmissions as well as high power density and transmission efficiency are very high. For the engineer, this means a whole series of new challenges.

Read More