Design Tips for Linear Motion Systems in Washdown Applications

This article examines the sound engineering practices and design principles needed to ensure the performance of mechanical linear motion components in sanitary washdowns or chemically cleaned environments. Relevant regulations and agencies, washdown-compatible materials, and best mounting practices and motion components for washdown applications are also discussed.

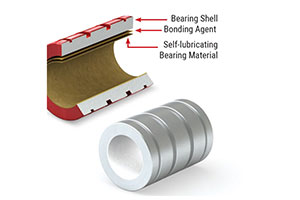

A Shift in Bearing Architecture

Randy Stott, publisher of Power Transmission Engineering and Gear Technology magazines, recently sat down with Norm Parker, technical fellow and technical manager for Torque Transfer Systems at Stellantis, to discuss bearing technology during the Motion + Power Technology Expo in Detroit.

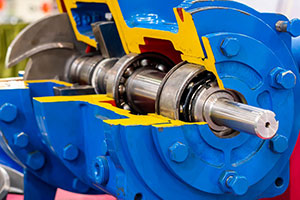

Bearing Design Considerations for Pumps and Compressors

Rolling bearings are integral to the operation of pumps and compressors and must be able to withstand moderate to heavy loading and harsh operating environments. A wide variety of ball, roller, and needle bearings can be found in these machines; however, this article will focus on the most common type of bearing used, the deep groove ball bearing.

White Paper: Brushed vs. Brushless Motors

Discover the differences between the two primary DC motor technologies in this comprehensive white paper. Readers will gain a better understand of the function, design, and implementation of the BLDC and PMDC motors. To conclude, we will provide some points to remember for the selection process of a DC motor for your upcoming applications.

Read Now

Split ring angular contact bearings offer greater thrust capacity

The NES Split Ring bearing is a single-row angular contact bearing supporting axial loads in both directions, reducing overall size and weight compared to traditional duplex sets. Additionally, pairing an NES Split Ring and standard ACBB doubles the load capacity in the primary load direction. Contact NES to learn more.

Read More

Tools Designed for Superior Performance

Get the right tools right now. QBC/BETEX Impact Fitting Tool Sets enable quick, safe, and precise mounting of bearings, bushings, sealing rings, cam wheels, and pulleys. Eliminate unnecessary damage to shafts, bearing houses, and sealing rings with these specially designed tools.

Read More

Cost-effective Bearing Solutions and Services from AST

AST is your go-to source for precision industrial bearings, power transmission components, and related value-added services. We also offer custom-designed bearings and rotary sub-assemblies, manufactured to your specifications. Learn how AST Bearings can provide you with “Value Beyond The Part™”.

Explore Products and Services

Stop seeing individual parts. Start seeing unlimited possibilities.

We know your industry, we understand your applications, and we know what it takes to achieve your objectives. From design and sourcing, to installation and condition monitoring—our team of experts and engineers sees the "big picture" and can help you unlock ultimate performance.

Read More

High Performance Spiral Bevel Gearboxes

With more models, sizes, and ratios, DieQua's spiral bevel gearboxes offer precision, performance and durability far above standard products. They're ideal for applications requiring high speed, precise motion control, high torque, or heavy shocks. Several configurations, options, and customized solutions provide unmatched design versatility.

Read More

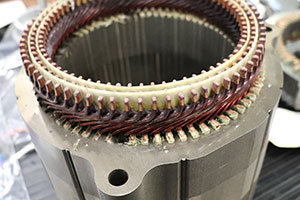

High Performance in Rotating Machinery: NSKHPS

For reliability in motors, pumps and fans, NSKHPS Cylindrical Roller Bearings deliver high loads and high speeds with low heat generation. An optimized design with superior roller guidance results in low wear and long operating life.

Read More

Join Us For Gear Materials

AGMA is hosting our Gear Materials on January 30 - February 8 online! For more information such as dates and times and registration deadline, click on the link below.

Register Now

2024 Fall Technical Meeting Call for Papers | Abstracts Due 19 January 2024

The 2024 Fall Technical Meeting (FTM) will be in Chicago, IL, from October 7–9. We encourage gear industry experts and professionals to submit an abstract. All abstracts must be completed and submitted in full by January 19, 2024.

Learn More