3DEO Wins Grand Prize at 2023 Design Excellence Awards

3DEO, the Torrance-based design, engineering and manufacturing firm and world leader in metal 3D printing, has won two awards at the PowderMet & AMPM2023 show last week in Las Vegas, NV. The company won the Grand Prize for Medical/Dental Application and an Award of Distinction for the Hardware/Appliance Category at the 2023 Design Excellence Awards.

Fail Better

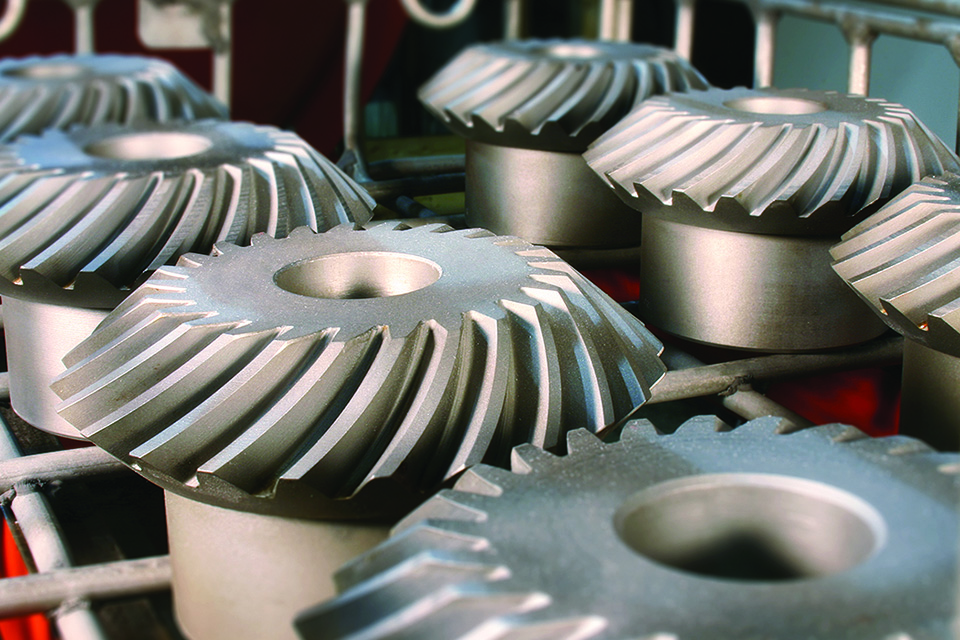

AGMA has published a failure nomenclature document, AGMA 944-A19, Mechanisms of Powder Metal, PM, Gear Failures. It is written similarly to ANSI/AGMA 1010-F14 but covers powder metal gear-specific failures over 30 pages and includes 11 detailed color figures. AGMA’s goal for the next revision of ANSI/AGMA 1010 is to incorporate powder metal gear failures and expand the standard to include plastic gear failures—definitions never published by AGMA before.

Post Additive Mfg. Heat Treating Vacuum Furnaces

ECM VACUUM FURNACES provide systems from single to multiple continuous batch production with robotic automation. No matter the process you are using for post additive heat treating, stress relieving, debinding, sintering and heat treating - ECM has your solution. ECM equipment meets all medical, automotive and aeronautics production requirements.

Read More

Technology for Gear Solutions

Miba Sinter Group is the technology leader in powder metal applications offering a wide variety of production processes. Semi-finished (near-net) blanks finalized by partner gear manufacturers deliver reduced machining time, waste, and costs. Net-shape spur and helical gears with NVH performance, high strength and precision, and cost-optimized design and production.

Read More

Over 60 years, engineers have relied on Spiroid® gearing.

From robotics to aerospace, our gears provide the most compact, highest torque and customizable solutions on the planet. It’s the perfect balance of torque, efficiency and ratio flexibility.

Find out if Spiroid Gearing is the best fit for your application. Consult our engineers directly today at 320-762-7133.

VISIT OUR CASE STUDY LIBRARY

Built-for-Stock—Fast Delivery of UBQ Batch Furnace

AFC-Holcroft's innovative Built for Stock program offers us the ability to deliver equipment weeks or months earlier than typical build-to-order delivery. Best of all, there is no extra cost for this accelerated delivery. This program features popular equipment such as batch furnaces, EZ endothermic gas generators, and support equipment.

Read More

Generate Gas On-site for Energy Efficiency

Surface® Combustion’s RX® Endothermic Atmosphere Gas Generators create the ability to generate gas on-site which saves on logistic and shipping costs. The modular design allows for a specific flow range of consistent quality gas to be precisely developed to optimize your gear production.

Surface Strong for Over 100 Years.

Read More

Low Pressure Carburizing of Gears

Solar Atmospheres provides low pressure carburizing (LPC) that significantly increases the surface hardness/strength of steel parts for improved friction and wear. Performing LPC in a vacuum furnace eliminates oxygen and prevents IGO (intergranular oxidation) that is inherent in atmospheric carburizing, resulting in clean parts with less distortion reducing post process finishing operations, and costs.

Read More