|

Get the freshest updates on gear technology

|

|

|

|

| Next Steps in Artificial Intelligence |

Representatives from Mercedes, Siemens, Beckhoff, Arburg, Hawe, KSB and Sick, among others, spent three days this summer discussing the relationship between humanoids and AI, the revival of reinforcement learning and AI utilization. As AI implementation becomes easier for manufacturers, the focus is evolving to address challenges and new opportunities across the entire industrial sector.

|

|

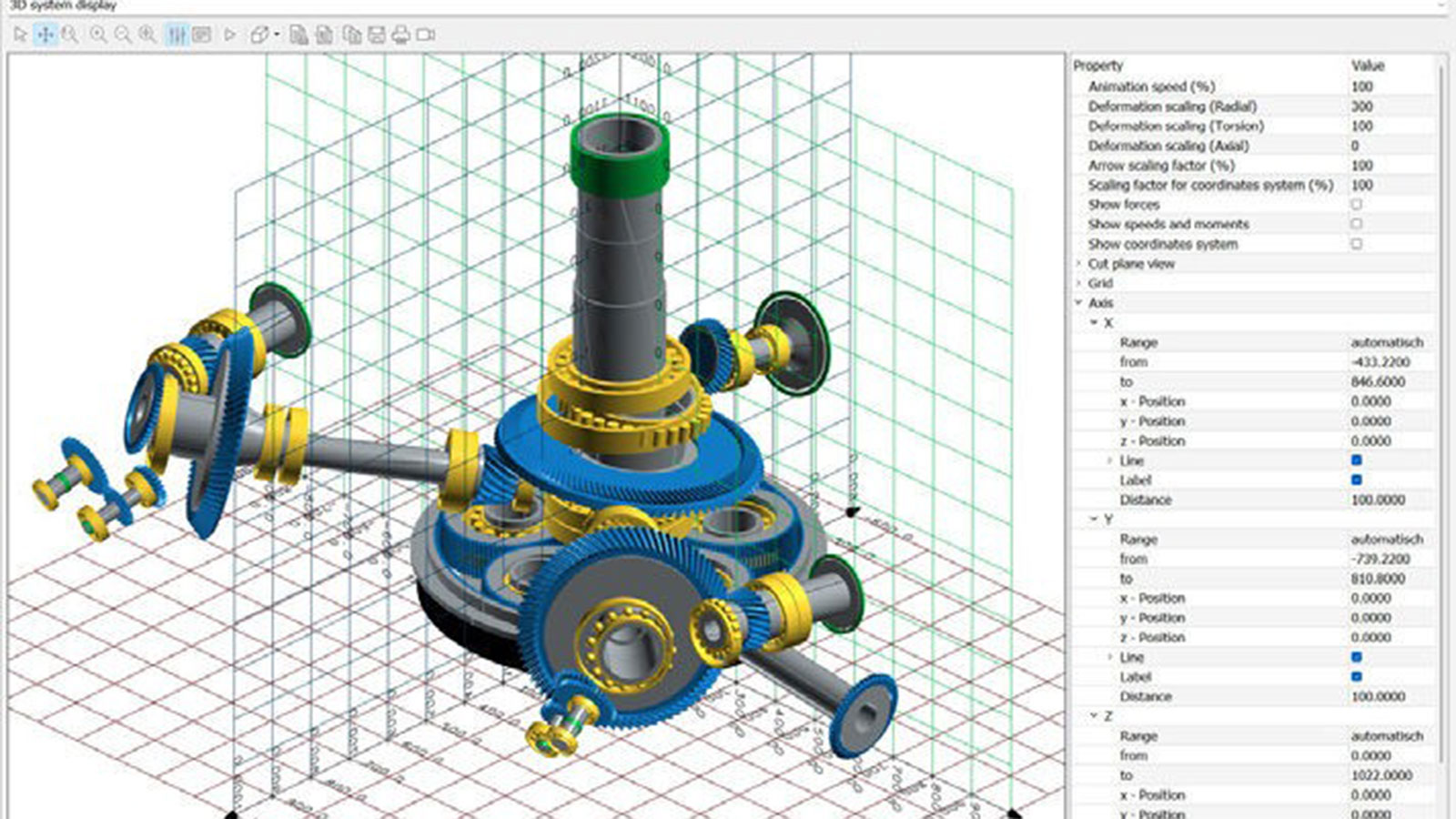

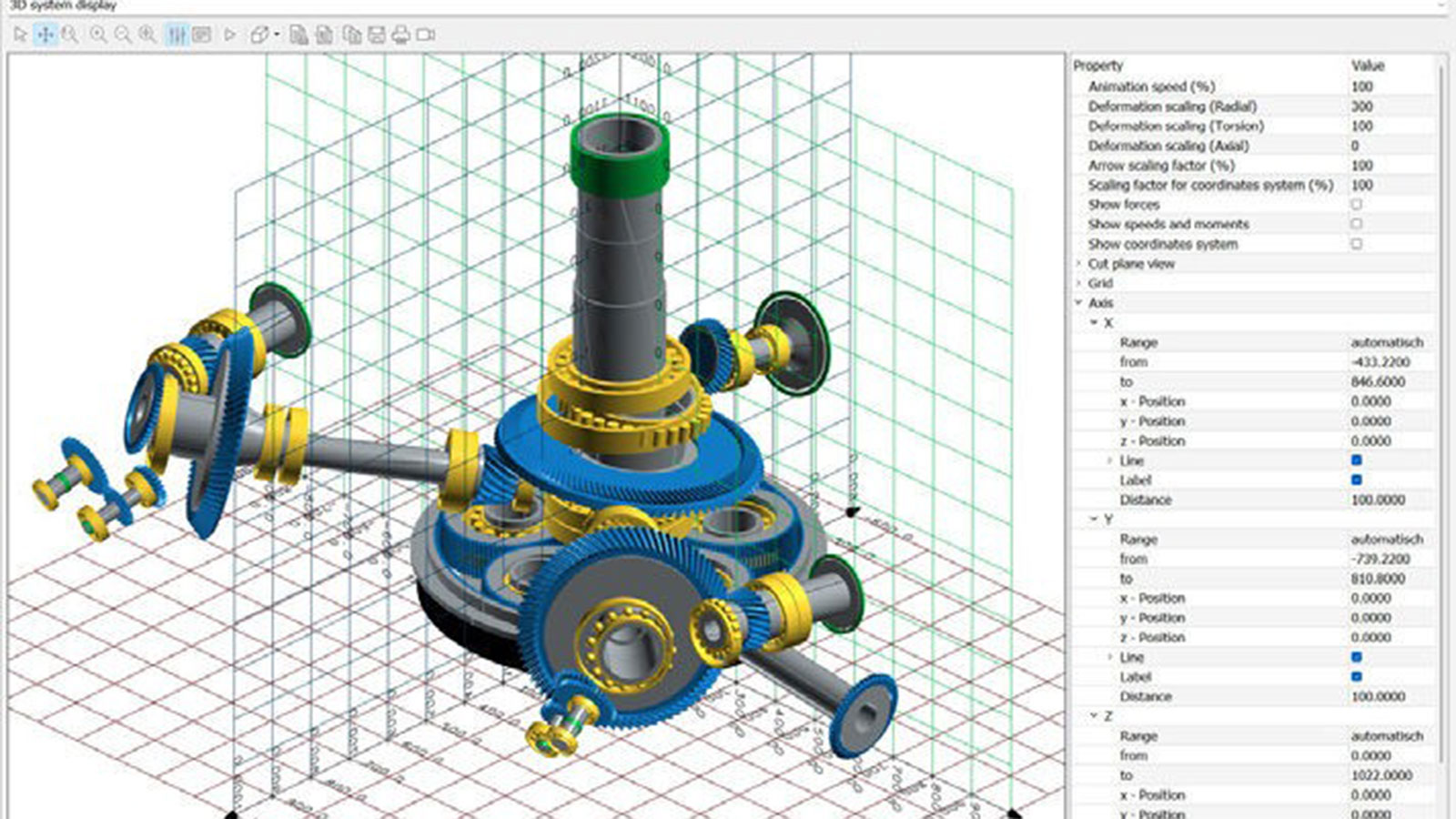

| Streamlining Drivetrain Design |

KISSsoft System Module allows intuitive concept design on a system level. In addition to the elementary components, complete gearboxes can now be designed in a separate module. The focus lies on fast concept building and fast calculations of complex kinematics. This is of benefit particularly in the initial phase of a project, when an engineer needs to be able to roughly model different variants of possible solutions to compare critical criteria.

|

| [Sponsored Content] |

|

| Re-build AND Re-control: Unleash Modern Performance from Legacy Gear Machines |

Struggling between costly new CNC gear machines and aging legacy equipment? There’s a smarter path. Re-build and re-control your existing gear machines to combine rugged iron with modern CNC intelligence. Achieve near-new performance, boost uptime, and lower costs—turning your old machines into strategic competitive assets.

|

|

|

|

| KISSsoft Design Software Release 2025 |

KISSsoft Gear Design Software is used in various industries, including electric vehicles, wind power, agriculture, marine, robotics, aerospace, and many others. Thanks to the synergies within the Gleason group, numerous features along the Design – Manufacturing – Measure initiative will be added to KISSsoft. Currently, the KISSsoft “Rollout” function calculates and visualizes cylindrical gear geometry, tolerances, and machining effects, ensuring proper meshing and form diameter evaluation. The new “Hobbing” function estimates cutting times, tool wear, and hobbing costs, providing a detailed process and interference analysis. KISSsoft supports gear designs combining efficiency and durability with low manufacturing costs!

|

|

|

| Automate gear calculations to save time and reduce errors |

Managing gear variants is time consuming. FVA-Workbench automates recurring tasks, from gear modeling and updating catalog data, optimizing gear performance to report generation – all in one system. Process variants simultaneously and deliver reliable, reproducible results for design, validation, and customer communications.

|

|

|

|